Have you ever thought about the unsung heroes of industrial storage? Internal Floating Roof (IFR) tanks stand guard, protecting a range of valuable liquids, from petroleum products to various chemicals. In this complex process of containing and releasing, secondary seals play a vital role, quietly reducing emissions and strengthening environmental safety. Yet, there’s a hidden factor that significantly affects how well they work—polymer content. This important element greatly influences their performance and longevity. In this blog, we’ll delve into the importance of polymer content in secondary seals and its crucial role in ensuring good performance.

The Struggles Within the Industry

Think about the challenges people face when trying to find the right secondary seal. It can be frustrating with all the testing and trials, and often, compromises have to be made. It’s not just about making a barrier, but about creating a seal that can handle changes in temperature, reactions with chemicals, and meet strict rules. These difficulties are something many people dealing with secondary seals can relate to.

Customized Secondary Seals

Imagine a custom-made outfit, carefully tailored to fit someone perfectly. That same level of care and precision goes into making customized secondary seals. These seals are designed with great detail to match the specific measurements of each tank. This ensures a snug fit and strict adherence to air quality rules. One important aspect of these seals is that they can consistently apply pressure around the floating roof’s edges and at every point where they touch the tank’s surface.

Importance of Polymer Content and it’s Role

Polymer content refers to the proportion of polymer material within the secondary seal. Polymers are materials made up of large molecules formed by repeating subunits, and they exhibit diverse properties based on their composition.

The key lies in understanding the significance of polymer content—a critical factor that influences the performance of secondary seals. Finding the right polymer content ensures a delicate balance between flexibility, chemical resistance, and durability—qualities that are essential for a secondary seal to excel in a demanding tank environment.

Importance of Polymer Content and Factors that Influence Selection Polymer Content

The decision on polymer content is far from arbitrary; it’s a balance struck through the interplay of several factors:

- Tank Design and Seal Configuration: Each tank has its own structural nuances, necessitating a tailored approach to the secondary seal. The polymer content must align with the specific design to ensure optimal fit and function.

- Polymer Types and Properties: Different polymers, such as EPDM, nitrile, polyurethane, and FKM, offer varying attributes. The polymer content is chosen to harness the polymer’s strengths and mitigate its weaknesses.

- Stored Product and Chemical Compatibility: The type of liquid stored in the tank influences the choice of polymer content. Compatibility is essential to prevent chemical interactions that could compromise the seal’s integrity.

- Temperature Variations: Tanks are subjected to fluctuating temperatures, from scorching heat to freezing cold. The polymer content should accommodate these variations, preserving flexibility even under extreme conditions. Regulatory Compliance: Environmental regulations, focused on reducing emissions, dictate the secondary seal’s effectiveness. The polymer content ensures compliance without compromising functionality.

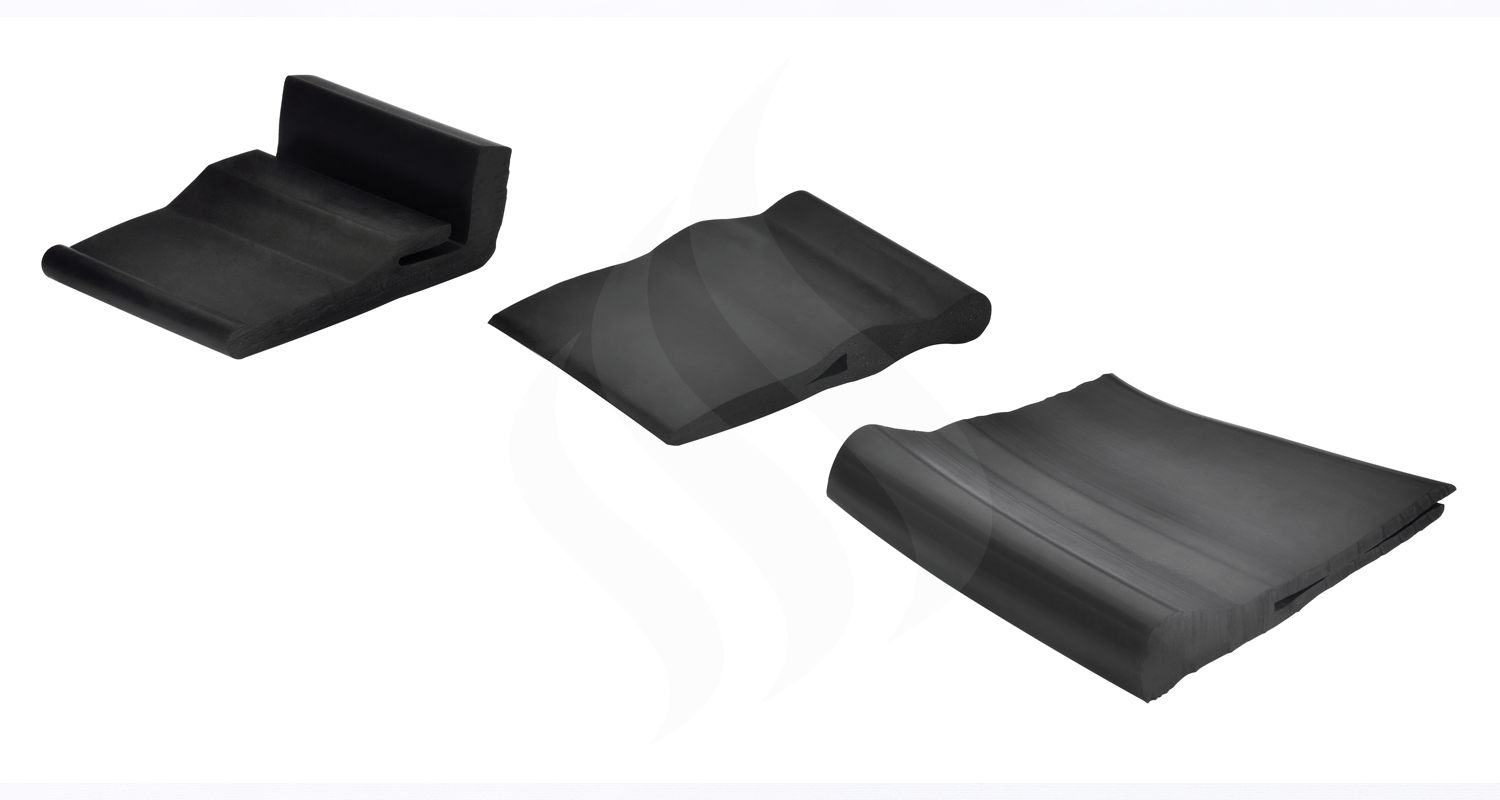

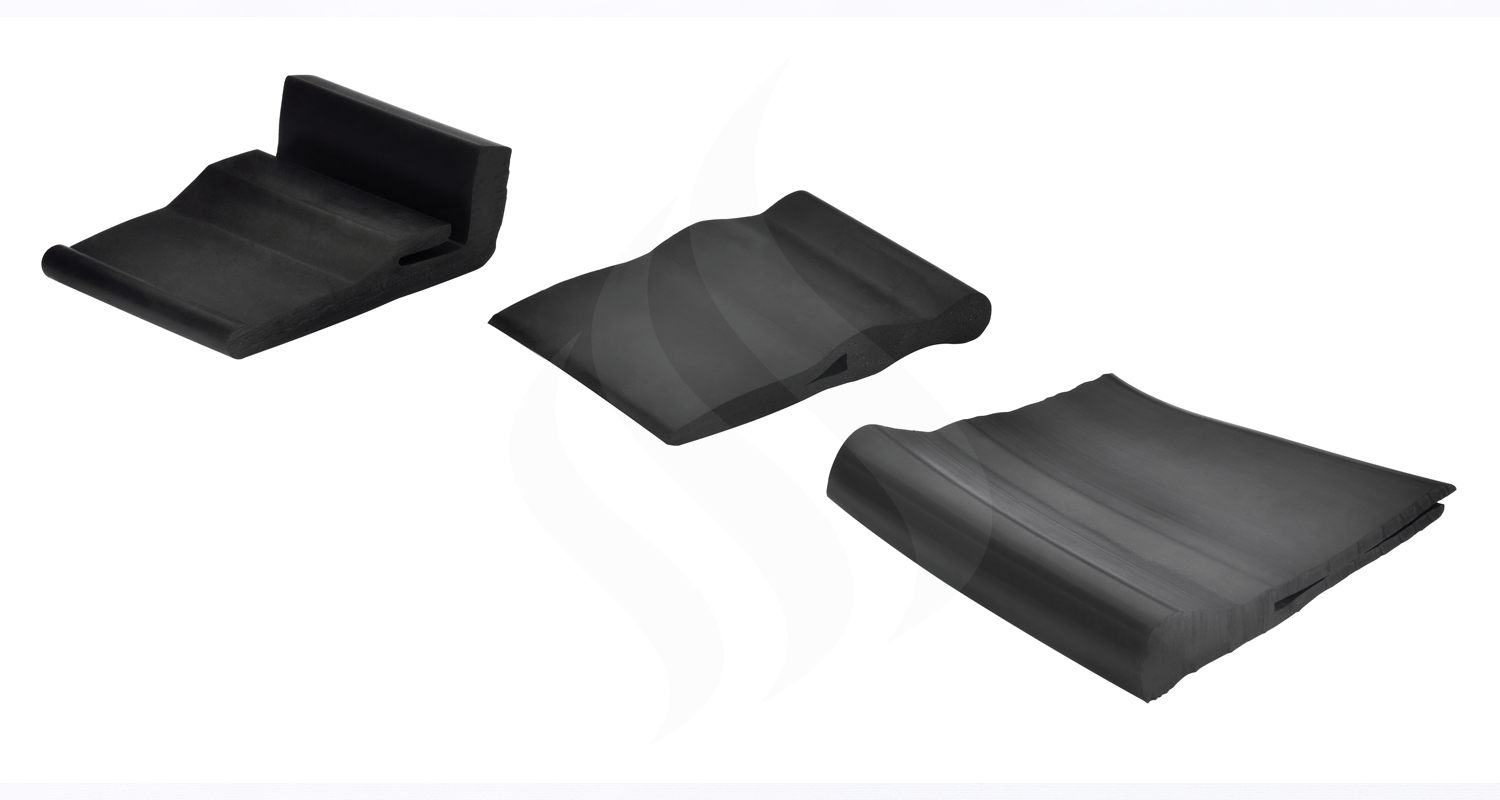

SagaSure Wiper Tip for Internal Floating Roof Tanks (IFRT)

In understanding the intricate challenge of secondary seal design for internal floating roof tanks (IFRT), we at Saga Elastomer embarked on a journey that redefined sealing excellence. As manufacturers who understand the complex interplay between precision, environmental responsibility, and operational efficiency, we unveiled a groundbreaking solution—SagaSure wiper tip for IFRT. This innovative creation has revolutionized sealing dynamics and elevated the performance of IFRTs to unprecedented heights.

What sets the SagaSure wiper tip apart is its comprehensive set of features and benefits, each meticulously designed to address the intricacies of IFRTs:

- Ozone Resistance: Crafted with a keen eye on the environment, the SagaSure secondary seal stands strong against ozone, ensuring long-lasting performance that endures the test of time.

- Evaporation Loss Reduction: In the constant battle against evaporation loss, the Saga wiper tip emerges as a stalwart ally, effectively reducing loss and preserving valuable product.

- Tailored for IFRTs: SagaSure wiper tip seal systems are custom-tailored for IFRTs, serving as secondary seals that go beyond mere containment. They prevent product loss and thwart atmospheric contamination, underlining Saga’s commitment to environmental stewardship.

- Robust Design: Boasting high tensile strength and excellent abrasion resistance, the SagaSure secondary seal maintains a lightweight and flexible design that doesn’t compromise on durability.

- Vapor Tight Splicing: Ensuring the integrity of the seal around the tank diameter is crucial. SagaSure wiper tip offers vapor tight splicing options that ensure a seamless and robust seal.

- Length Considerations: Saga recognizes the importance of minimizing joints in the sealing system. Hence, our wiper tips can be manufactured in lengths of up to 25 meters, contributing to the seal’s effectiveness.

- Wide Range and Customization: Embracing diversity, Saga manufactures a wide range of IFRT wiper tip seals. What’s more, we provide customization options to cater to your specific needs, ensuring a snug fit for your tank.

Saga Elastomer’s Nitrile PVC Solution

At Saga Elastomer, our commitment to innovation yielded a tailored solution—the nitrile PVC secondary seal. With a polymer content of 50.52%, our nitrile PVC blend captures exceptional chemical resistance, unparalleled flexibility, and remarkable abrasion resistance. It’s a solution that strikes the perfect balance for the demands of internal floating roof tanks.

Elevating Secondary Seal Performance for Tank Efficiency

As you tread the intricate path of secondary seal design, we invite you to engage with our expertise. Discover our nitrile PVC solution and harness the power of optimal polymer content in secondary seals. Drive the performance of your internal floating roof tanks to new heights with SagaSure.