Rubber is highly elastic, durable and is corrosion resistant. It has good weathering property, is water resistant, an electrical and thermal insulator, and is able to absorb movement and vibration.

Rubber is commonly used in the infrastructure industry for:

- Sound, vibration and impact absorption

- Joints, seals and gaskets

- Coatings, paints and sealants

- Pipes and cabling

- Belting

- Membranes

- Protective clothing

- Roofing and flooring

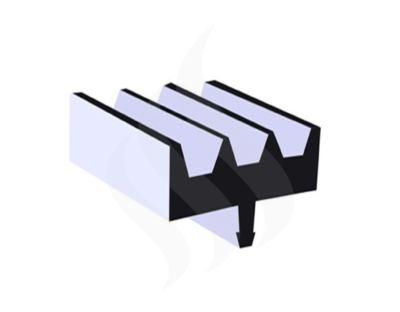

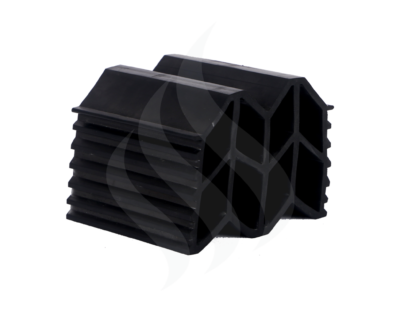

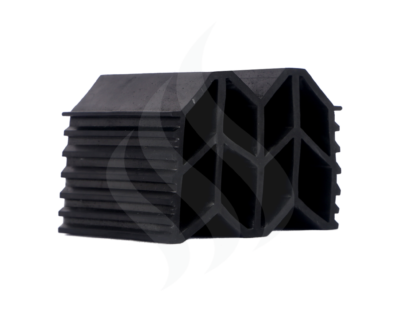

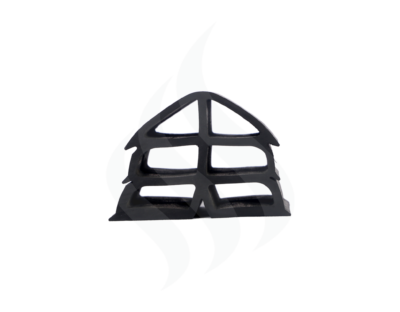

Saga EPDM pads for Road Over Bridges- The structural joints for bridges have an assembly structure screwed as per customization and the union with the groove of the mouth. The internal reinforcement plate makes said joint able to support the load of several vehicles, with a certain vertical rigidity. Due to the incompressibility of the rubber, the specially formed rubber plate indentation prevents the telescopic joints from swelling when compressed.

Features & benefits

- Excellent anti-ageing

- High compression set properties ensure high durability

- Low replacement costs

- Wide range

- Customization options available

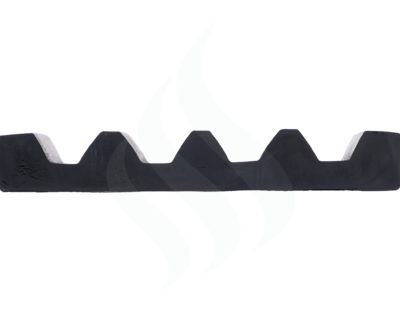

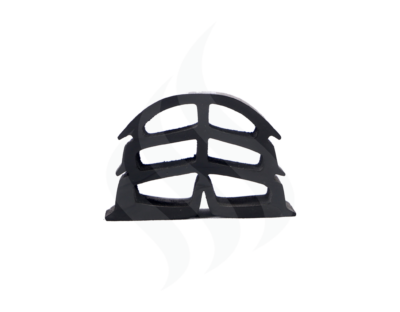

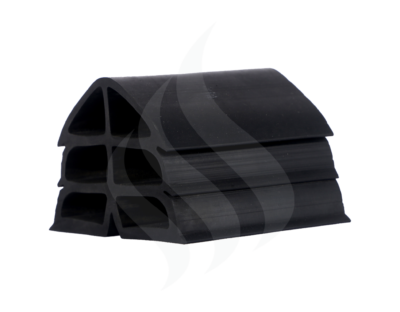

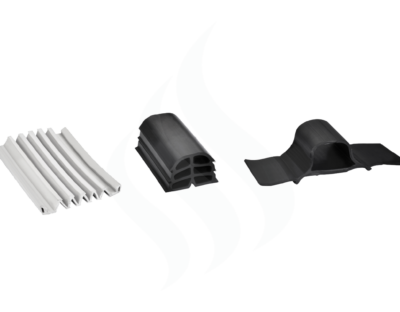

Saga weighbridge rubber profile perfectly sits in the gap around the outside of a weighbridge. It ensures prevention of grit, dirt & stone from falling inside. Prevents mechanical failure, expensive repairs and reduce its operational life. EPDM is able to compress while in use enabling our product to provide excellent sealing capabilities at all times. Despite offering good compression rates, EPDM also features good “shape memory”, which enables the product to return to its original shape.

Features & benefits

- High quality materials

- Smooth finish

- Highly durable

- Weather resistant

- Prevent dirt & grit build up

- Preserve weighbridge usage

- Good weathering

- UV & ozone resistance

- Impact and pressure resistance

- Easy to install

- Wide range

- Customization options available

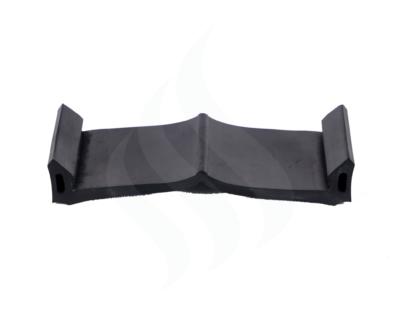

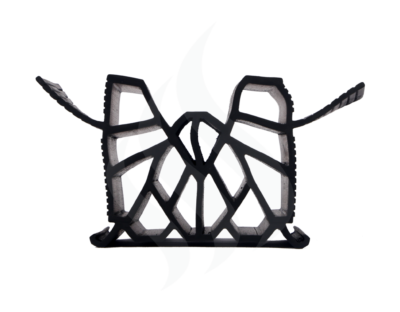

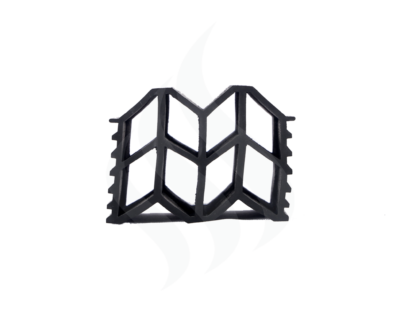

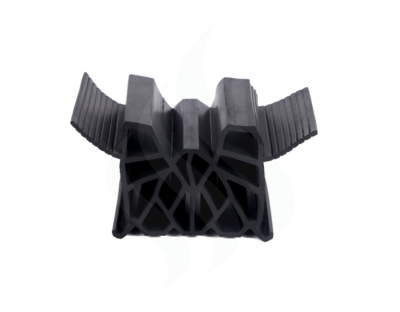

Saga EPDM expansion joint is an assembly designed and manufactured to absorb the temperature-induced expansion, contraction and vibration of roads, bridges, etc. It helps keeping different parts together, allowing movement during ground settlement or earthquakes. Saga expansion joint profiles are used on the bridge joints and similar structures to transfer forces from the superstructure to the substructure.

All building materials have a coefficient of expansion. This coefficient is a function of the temperature variation, that is, with an increase in temperature the material dilates and with a decrease in temperature the material contracts. It is therefore necessary to provide an area where these great stresses can be “absorbed” in the expansion joints.

Saga manufactures expansion joint profiles which are easy to install and highly durable. These expansion joint profiles are generally installed on floor, sealed with a special glue. Internal cell’s design allows up to 50% multi directional movements while maintaining sufficient lift to absorb all the traffic. These profiles are recommended to be installed minimum 5mm below floor level.

Features & benefits

- Excellent anti-ageing

- High compression set properties ensure high durability

- Low replacement costs

- A vast range of existing tools gives an edge to end users

- Wide range

- Customization options available

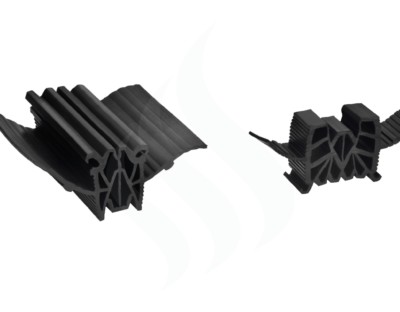

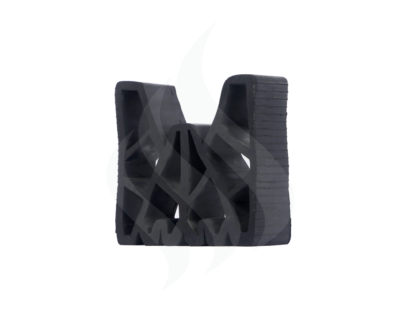

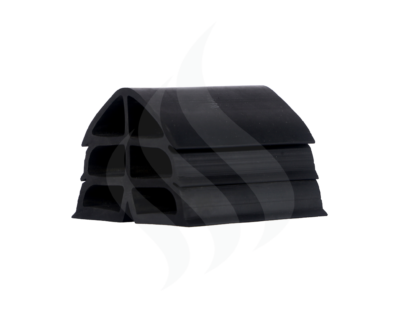

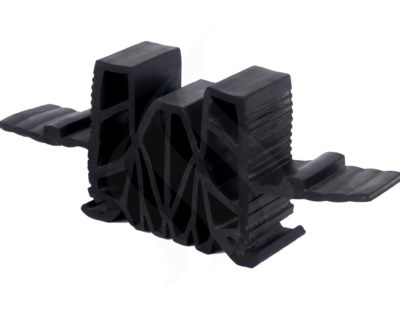

Saga Neoprene expansion joints are specially formulated to offer a very high durability exposed to the elements as well as adequate resistance to compression, they are used to control the interaction of loads, movements between the beams and piers that support a certain structure, whose use mainly is on the bridges; they are part of a structural assembly, helping to normal displacement and partially absorbing the energy of the thermal expansion of the beams.

Neoprene is an elastomer with excellent mechanical and abrasion properties, it has the required physical properties and is highly resistant to deterioration. Neoprene’s compressive strength is more than enough to withstand bridge loads.

Features & benefits

- Excellent anti-ageing

- Excellent mechanical and abrasion properties

- Highly resistant to deterioration

- High compression set properties ensure high durability – Loads up to 79 Kg/Cm2

- Provides safety to the structure

- Durability-low replacement costs

- A vast range of existing tools gives an edge to end users

- Wide range

- Customization options available