Chemical, Oil & Gas Distribution

Storage tanks are used throughout the oil and gas industry for the bulk containment of fluids at different stages of the refinery process. Most often, products are stored for a short time before being transported for further processing.

The two most common types of tanks used for these applications are

- Fixed Roof Tanks

- Internal Floating Roof Tanks (IFRT)

Fixed Roof Storage Tank design minimizes the risk of structural failure and potential damage to the environment. Floating Roof Storage Tanks Many tanks are designed with a roof that floats on top of the liquid. The floating roof moves up and down as the level of liquid in the tank changes during filling, emptying or with ambient temperature variation. A floating roof minimizes the amount of vapor between it and the liquid, leaving little space for evaporation and reducing vapor losses. In many older tanks, the floating roof is merely a large flat disc covering the surface of the liquid. However, in recent years, the design of internal floating roof tanks has substantially improved to minimize vapor loss.

Floating roof storage tanks share many of the features as fixed roof tanks with a major difference of seal. The secondary seal is called Wiper Tip for internal floating roof tank (IFRT).The rubber element of the secondary seal during its functionality is exposed to the following conditions:

- On one side it faces exposure to weathering conditions –sunlight/ozone / rain all climatic conditions – hence it needs good ageing properties, resistance to ozone and sunlight

- On the other side it is in contact with the liquid which the tank is storing along with volatile gases of the liquids stored – hence it needs good resistance to hydrocarbons /fuels

- It abrades with the shell of the tank as the roof moves up and down and is physically clamped by bolts – hence it needs good abrasion resistance and sufficient tensile properties

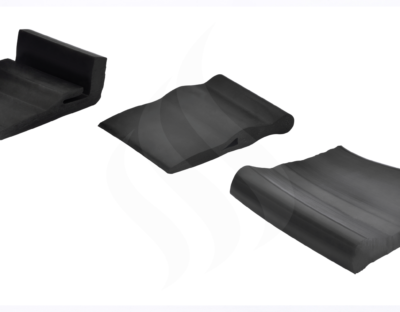

- The shape/profile of the seal is best decided by the tank seal system manufacturer

Saga wiper tip for internal floating roof tanks (IFRT)- Saga wiper tip for IFRT is a strip of nitrile rubber mixed with other polymers & is used to provide a seal between the rim of the floating roof and the tank shell to reduce vapor leakage. The Saga wiper tip is ozone resistant and can further reduce the evaporation loss very effectively.

Saga wiper tip seal systems are used as secondary seals in internal floating roof tanks (IFRT). These wiper tips are specially designed to prevent product loss and atmospheric contamination from internal floating roof tanks (IFRT). Saga wiper tip seal systems are designed to ensure effective operation in specific tank conditions. Saga manufactures multiple options of IFRT wiper tip seals customized as per your choice to ensure the best fit for your tank.

Saga Wiper tip seal is made from specially engineered Nitrile PVC compound to achieve properties best suitable for this application like – fuel resistance , abrasion resistance , ozone resistance.

We have achieved the best of these properties in our Nitrile /PVC blend compound

Features & benefits

- High tensile strength

- Excellent abrasion resistance while maintaining a lightweight and flexible design

- Offers vapor tight splicing options that maintain the integrity of the seal around the tank diameter

- We can make lengths of up to 25 meters to minimise joints in the sealing system

- Wide range available

- Customization options available