Introduction

Rubber gaskets are often overlooked, but they do a lot of heavy lifting. They keep water out, seal in temperature, and help curtain walls and windows perform the way they should. But when these gaskets fail—and they often do—it leads to drafts, leaks, higher energy bills, and mounting complaints.

In this article, we’ll look at what really causes gasket problems, how to avoid them, and why choosing the right type—especially thermal insulation rubber gaskets for windows—can save you a lot of trouble (and money) down the line.

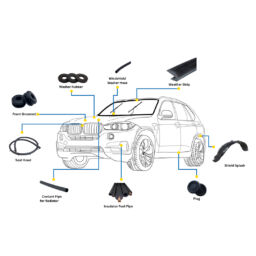

What Do Rubber Gaskets Actually Do?

- Weatherproofing: They block wind, rain, and airborne debris.

- Thermal Insulation: They reduce heat transfer through window joints.

- Movement Buffer: They allow buildings to flex without breaking seals.

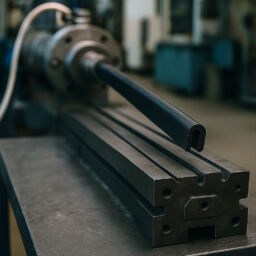

Materials like EPDM and silicone are preferred for high-rise, glass-heavy facades and double-glazed windows.

Why Gaskets Fail in Curtain Walls and Windows

1. UV Exposure

Too much sun causes non-UV-stable materials to crack and shrink.

2. Temperature Swings

Daily heating and cooling cause expansion and contraction that wears down lesser materials.

3. Poor Installation

Wrong fit or incorrect placement often causes early failure.

4. Low-Grade Rubber

Cheap rubber doesn’t last under pollution, rain, or cleaning chemicals.

5. No Maintenance

Even good gaskets wear out. No checks mean no early fixes.

Which Rubber Gasket Material Works Best?

| Material | UV Resistance | Temperature Range | Flexibility | Typical Lifespan |

| EPDM | High | -40°C to 120°C | Excellent | 15–20 years |

| Silicone | Very High | -60°C to 200°C | Excellent | 20–25 years |

| Neoprene | Moderate | -30°C to 100°C | Moderate | 8–12 years |

| NBR | Low | -25°C to 100°C | Moderate | 5–10 years |

If you’re sealing high-performance glass facades, go with EPDM or silicone. They don’t chalk, crack, or give up under pressure.

How Gasket Failures Kill Energy Efficiency

- Gaps let hot or cold air in, overworking HVAC systems.

- Indoor temperatures become harder to control.

- Moisture leads to condensation and mold.

- Energy certification goals like IGBC or LEED become harder to meet.

Example: A commercial tower in Chennai saw HVAC bills climb by 16% due to worn-out EPDM. Silicone replacements fixed it fast.

How to Prevent Rubber Gasket Failures

- Choose gaskets made for UV, wind, and extreme heat.

- Use profiles that match the window or curtain wall frame exactly.

- Inspect for cracks or separation at least once a year.

- Train your team on proper installation.

- Don’t wait for leaks. Replace aging gaskets on schedule.

FAQs

Which rubber profiles improve energy efficiency in curtain walls?

EPDM and silicone gaskets hold air longer and survive tough conditions.

Why choose UV-resistant silicone for skyscrapers?

It bends without breaking, seals tight, and resists sun damage.

Can I retrofit gaskets on older windows?

Yes. You can upgrade to thermal insulation rubber gaskets for better results.

Final Thoughts

Most gasket failures don’t happen overnight. They start small. A crack here. A draft there. Then—water, complaints, energy waste.

Don’t wait until things break. Use better materials. Check your gaskets regularly. Train your team well.

Need help choosing the right gasket for your building?

SEPL’s EPDM and silicone gaskets are made to last under sun, heat, and pressure.

Reach out for samples, data sheets, or expert guidance today.