Coastal areas are among the high-risk zones where constructing structures is extremely critical. Building a facade system for coastal projects demands high performance, durability, and resilience. The most important component that makes or breaks the facade system is the rubber extrusion. It helps to maintain an effective barrier against environmental challenges. Hence, choosing the right rubber profile prevents premature seal degradation, structural damage, and water ingress, leading to costly replacements.

In this blog, we explore the five key specifications that must be assessed when choosing the appropriate rubber extrusions for coastal projects.

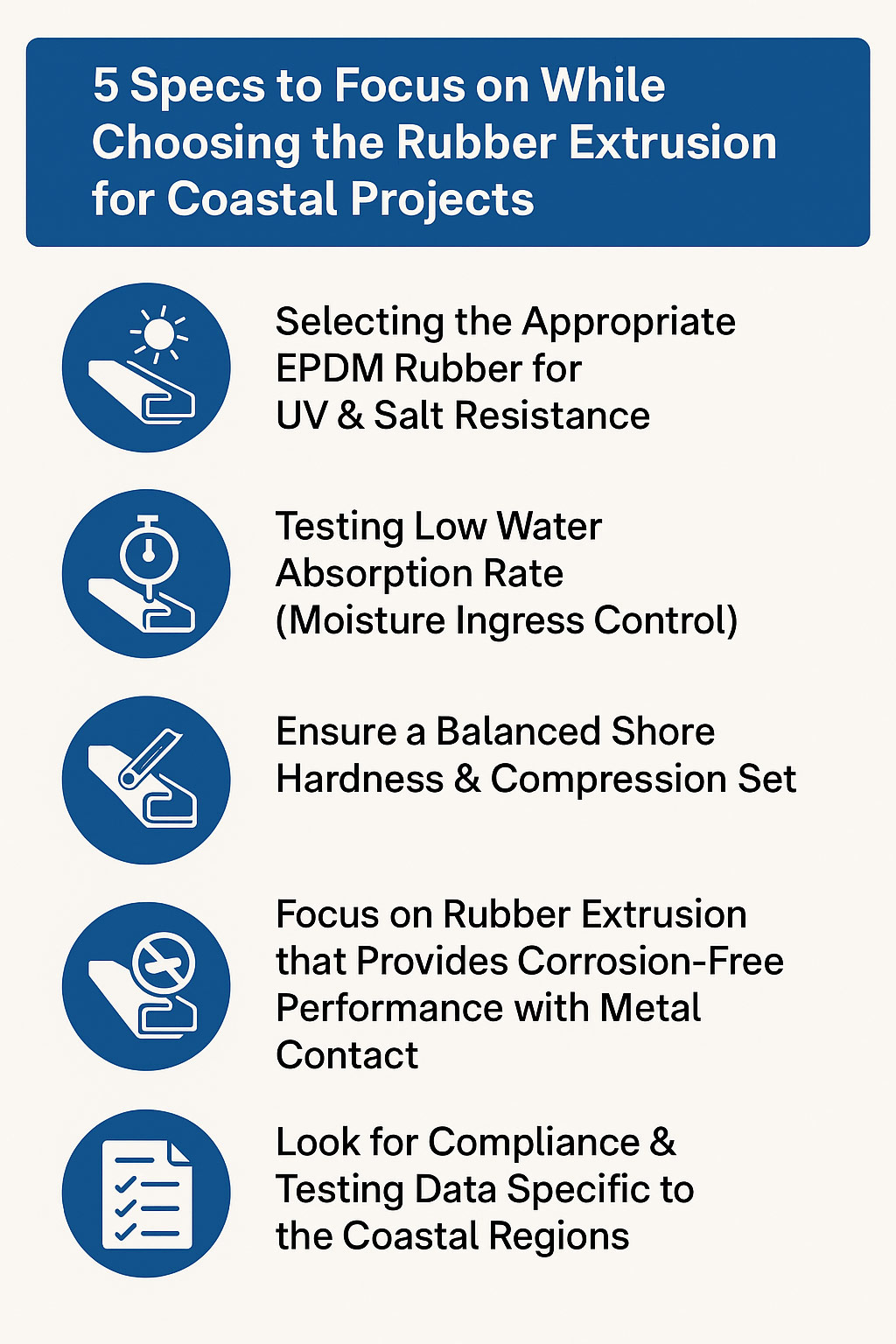

- Selecting the appropriate EPDM Rubber seals for UV & Salt Resistance

- Testing Low Water Absorption Rate (Moisture Ingress Control)

- Ensure a balanced Shore Hardness & Compression Set

- Focus on rubber extrusion that provides Corrosion-Free performance with Metal Contact

- Look for Compliance & Testing Data specific to the coastal regions

The above parameters, when followed accurately, would help ensure the high performance of building structures in the face of extreme salt spray, high humidity, UV rays, and temperature differences in coastal areas. Let’s deep dive:

1. Select the Appropriate EPDM Rubber UV & Salt Resistance

The coastal areas are exposed to persistent sunlight and a continuous barrage of salt-laden air. Both environmental factors are dominant elements leading to rubber seal degradation over time. The EPDM rubber is formulated to withstand salt-laden air, ozone, and UV light, making it a suitable material for coastal projects.

Specs to verify:

- Tolerance to salt spray exposure

- Mechanical stability over a wide range of temperatures

- Passed environmental tests like ozone (ASTM D1149) and UV ageing (ASTM D1171)

2. Testing Low Water Absorption Rate (Moisture Ingress Control)

Water ingress due to poor rubber sealing is one of the imminent causes of facade failures in humid coastal climates. Porous rubber extrusions can lead to water absorption, swelling, and degradation, resulting in air and water leakages into the interiors and structures of the buildings.

Specs to Verify:

- As per ASTM D471, the water absorption rate must be below 5%

- Seal designs that allow proper drainage, preventing water entrapment

Rubber materials behave very differently over time. Therefore, insisting on samples and lab test results is crucial while selecting the ideal rubber extrusion for facade. The design from Saga encompasses features that help in proper drainage and rapid drying, reducing the chances of water entrapment.

3. Confirm a Balanced Shore Hardness & Compression Set

While choosing the facade seals, ensure the rubber profiles create a tight barrier for air and water, and at the same time, are flexible to compress and return to the original shape. Seals collapse when they are too hard. Balancing shore hardness and compression set, make sure that the rubber seals are functional over time, withstanding thermal expansion and mechanical stresses.

Specs to Verify:

- Shore Hardness ranging between 60-70 for optimum sealing

- Compression Set <25% after 22 hours at 70°C (ASTM D395)

Recycled and inconsistent raw materials used in the generic rubber profiles result in cracks and a loss of shape. Saga Elastomer has stringent manufacturing standards with high-quality compound delivering hardness, elasticity, and consistency supported by endurance tests.

4. Check for Corrosion-Free Performance with Metal Contact

Rubber extrusions in facade systems often encounter metals like steel, stainless steel, aluminium, etc. When the rubber material reacts chemically with these metals, it leads to galvanic corrosion, resulting in joint weakness and facade instability.

Specs to Verify:

- Salt spray test qualification ASTM B117

- Compatibility with aluminium and stainless steel

- Compounds that are non-staining and non-corrosive

5. Focus on Region-Specific Testing Reports and Compliance

Environmental challenges differ from region to region. For instance, coastal project sealants encounter harsh UV rays and salt-laden air as compared to regions with less environmental challenges. Therefore, depending on the generic specs can result in facade failure.

Specs to Verify:

- UV, humidity, and salt resistance test reports from certified labs

- REACH, RoHS, ISO 9001:2015 compliance certificates

- ASTM E331 (water), ASTM E283 (air), ASTM E330 (structural load) – facade mock-up testing reports.

Who Should Care About the Rubber Profile Specs?

The specs are vital factors for architects, designers, and several other stakeholders:

- Architects & Designers: Depend on reliable data to draft accurate specifications to meet client expectations

- Facade Engineers: Need components with their performance test reports to accurately validate the facade system

- Procurement Teams: Prefers to avoid the supply chain challenges and compliance issues during site execution

- QA & Maintenance Teams: Require proven durability data to ensure low maintenance costs over time

Standardization for Coastal Projects

Construction companies and architectural firms that largely handle coastal projects prioritize standardizing high-quality rubber seal profiles, as it helps them to create an easy cycle of –

- Speedy procurement

- Simple site replacements

- Low rubber profile validation costs

- Low facade lifecycle maintenance cost

Saga Elastomer: Your Partner for Coastal-Grade Rubber Extrusions

With decades of global supply footprints and experience in providing rubber profiles for coastal projects, Saga Elastomers delivers custom rubber extrusions to complex and demanding coastal projects worldwide. Our ISO 9001 and IATF 16948 Certifications, geography-specific R&D, and in-house testing labs propel us to manufacture custom rubber extrusions to fit your project environment and design.

Advantages of Saga Elastomer:

We offer cataloged options for different coastal zones. Our UV-stabilized rubber profiles have shown reliable performance over decades in projects near the sea, in India, GCC, Taiwan, and North Korea. Partnering with us, you get –

- Pre-tested EPDM rubber extrusions to combat the environmental conditions in the Gulf Cooperation Council (GCC) countries, Southeast Asia, and Australia.

- Full test report of every rubber profile, including region-specific tests.

- Assistance in Facade mock-up testing to ensure the seals pass the air, water ingress test before project commencement.

- Support for all stakeholders involved in the coastal projects to select the right rubber profile

Quick Checklist: Rubber Seals Performance Validation in Coastal Projects?

| Specification | Requirement | Saga Compliant? |

| UV & Salt Resistance | EPDM with ASTM D1149/D1171 compliance | Yes |

| Water Absorption Rate | <5%, closed-cell structure | Yes |

| Shore Hardness & Compression | 60–70 Shore A, <25% compression set | Yes |

| Non-Corrosive Material | Passes ASTM B117, non-reactive | Yes |

| Region-Specific Compliance | REACH/RoHS/ISO, mock-up test support | Yes |

Planning a facade system installation in a coastal or high-humidity region?

Partner with Saga Elastomer for high-quality rubber extrusion solutions that are field-tested and approved by architects. Avoid costly facade performance failures and ensure facade weatherproofing.