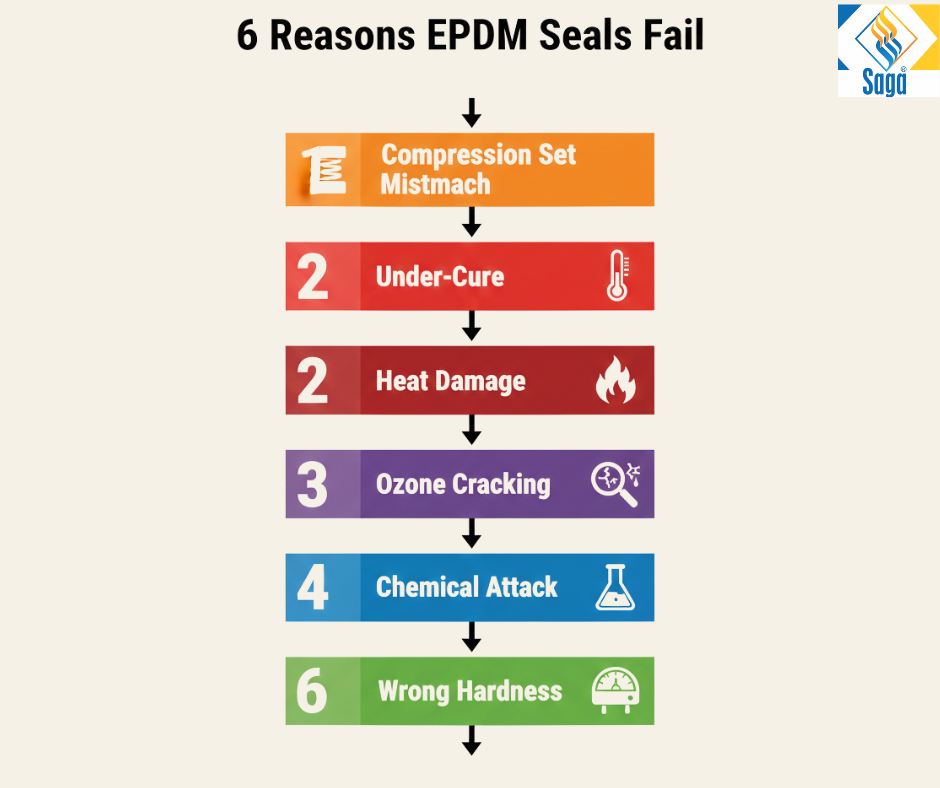

Why EPDM Seals Fail: 6 Common Problems and How to Fix Them Before They Happen

Have you ever wondered why your EPDM rubber seals fail even when you buy good quality material?

You’re not alone. Every year, thousands of engineers and procurement managers face this same frustration. The seal looks perfect in testing, but fails in real-world use. Water leaks appear. Cracks develop. The seal loses its grip.

Here’s the truth: EPDM seal failure is rarely about the rubber quality alone.

After three decades of manufacturing rubber seals at Saga Elastomers, we’ve seen the same problems repeat across industries—automotive, construction, solar, marine, and railway applications. The good news? Most EPDM seal failures can be prevented when you know what to look for.

In this guide, you’ll learn the six most common EPDM seal failure modes, how to spot warning signs early, and practical steps to prevent costly seal problems.

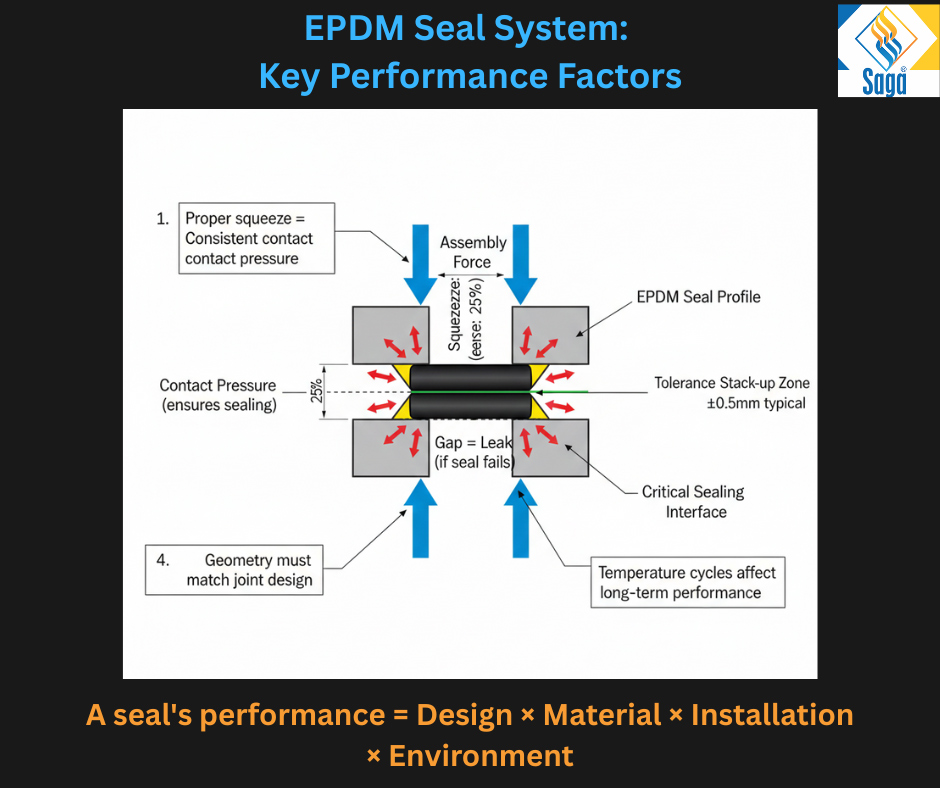

What Makes a Seal Actually Work?

Before we talk about failures, let’s understand what makes seals work.

A good seal is not just about the rubber material. It’s a complete system that includes:

Design of the seal profile

- Rubber compound formula

- Curing process

- How it’s installed

- The environment where it works

When even one of these elements doesn’t match real working conditions, you get problems: leaks, cracks, swelling, or early wear.

Think of it like a chain—it’s only as strong as its weakest link.

Problem #1: Good Test Results, Poor Real-World Performance

The Issue:

Your EPDM seal passes all compression set tests in the lab. The quality certificate looks perfect. But within weeks of installation, you see leaks.

What’s Really Happening:

Laboratory tests use standard conditions—controlled temperature, perfect squeeze, no movement. Real applications are messier.

In actual joints, you face:

- Uneven squeeze (parts don’t fit perfectly)

- Temperature changes (hot days, cold nights)

- Long-term stress that makes rubber slowly relax

- Pre-stretching during installation

Early Warning Signs:

- Seal becomes flat at tight spots

- Leaks appear after a few weeks, not immediately

- Problems worse after temperature cycles

How to Prevent:

Don’t rely only on standard compression set tests. Create a test that copies your actual joint conditions—real squeeze levels, temperature changes, and assembly stress.

Define a proper squeeze percentage window (usually 15-25% for most applications). Too little squeeze means no seal. Too much squeeze causes early failure.

Problem #2: Surface Looks Cured, But Inside Isn’t

The Issue:

The seal feels solid on the outside. It passes basic checks. But after a few weeks, it starts showing problems—sticky surface, weak corners, or changing hardness.

What’s Really Happening:

In thick EPDM profiles, the outside can cure faster than the inside. This is especially common with continuous curing systems or hot air curing.

The surface reaches the right temperature and looks “done.” But the core hasn’t received enough heat for enough time to fully crosslink.

Early Warning Signs:

- Surface feels tacky or picks up dust easily

- Corner joints are weaker than expected

- Hardness, bounce-back, or tear strength changes over 1-3 days

- Spliced sections perform poorly

How to Prevent:

Use proper curing equipment that heats the entire profile evenly. Don’t just rely on datasheet curing times—test your actual production setup.

Add simple factory checks: hardness readings 24 hours after production, surface tack test, and corner tear resistance.

Match your rubber compound’s curing characteristics to your actual heating equipment, not just to what the datasheet says.

Problem #3: Heat Damage (During Making or During Use)

The Issue:

EPDM seals develop a dry, brittle feel. They tear easily. Degradation appears near thick sections or areas that got hot.

What’s Really Happening:

Heat damage can happen in two ways:

During manufacturing: Processing hot spots, reheating material, or keeping rubber at high temperature too long.

During service: Working in high-temperature environments or temperature peaks beyond EPDM’s normal range.

Early Warning Signs:

- Dry or weak texture

- Tears spread quickly

- More damage near thick zones or hot exposure areas

- Color changes (darker spots)

How to Prevent:

Control your processing temperature carefully. Monitor hot spots in your curing system.

For high-temperature applications, choose the right cure system and add heat stabilizers. Standard EPDM works well up to 120°C continuously. For higher temperatures, you need special compounds.

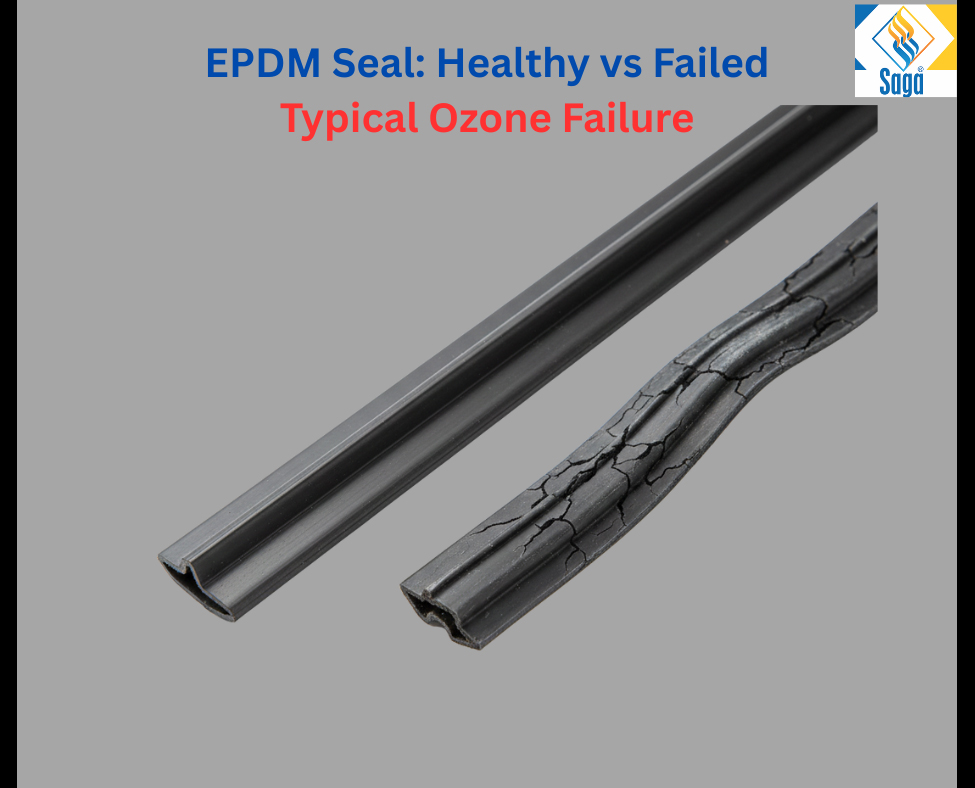

Problem #4: Ozone Cracks vs Installation Damage (Often Confused)

The Issue:

You see cracks in the EPDM seal. But is it from ozone exposure or from installation damage? The solution is completely different for each cause.

What’s Really Happening:

Ozone cracking and mechanical damage look different when you examine them closely:

Ozone Cracking:

- Very fine cracks, like hair-thin lines

- Cracks run perpendicular (at 90 degrees) to stretched areas

- Appears at corners, tight bends, or stretched sections

- Develops slowly over weeks or months

Installation Damage:

- Random cuts, nicks, or scratches

- Localized to specific spots

- Usually from sharp edges, tools, or excessive stretching during fitting

- Visible immediately after installation

Early Warning Signs (Ozone):

- Fine surface cracks in stretched zones

- Worse in outdoor or high-ozone areas

- No visible installation trauma

Early Warning Signs (Mechanical):

- Obvious cuts or gouges

- Damage along installation path

- Correlation with assembly tools or sharp edges

How to Prevent:

For ozone protection: Ensure your EPDM compound includes proper ozone-resistant additives. Reduce installation stretch. Use better corner radii.

For mechanical damage: Improve lead-in geometry. Remove sharp edges from metal frames. Train installers on proper fitting techniques. Use installation lubricants.

Problem #5: Chemical Compatibility Problems

The Issue:

Your EPDM “weather seal” works fine for months, then suddenly swells, softens, or develops an oily film. Or it hardens and shrinks.

What’s Really Happening:

EPDM is excellent for water, weather, and many chemicals. But it’s not universal.

Cleaners, lubricants, adhesives, paints, oils, or fuels can:

- Extract plasticizers from the rubber

- Cause swelling (rubber absorbs the chemical)

- Change seal dimensions

- Reduce sealing force

The tricky part? These chemicals often come from adjacent parts or assembly processes—not from the primary environment.

Early Warning Signs:

- Oily or sticky film on seal surface

- Staining on nearby materials

- Swelling or softening near contact areas

- Hardening or shrinking in other cases

- Color change

How to Prevent:

Test your EPDM seal with the actual chemicals it will contact:

- Assembly lubricants

- Cleaning agents used on site

- Paints or coatings on frames

- Adhesives or tapes nearby

- Any oils, fuels, or solvents in the environment

Choose plasticizers and process oils that won’t migrate easily. Sometimes paying slightly more for a compatible compound saves thousands in field failures.

Problem #6: Wrong Hardness for the Application

The Issue:

You selected 60 Shore A hardness because “it’s standard.” But you’re getting either leaks (too hard) or assembly problems (too soft).

What’s Really Happening:

Hardness is just one property. Sealing performance depends on the complete picture:

- Contact pressure between seal and surface

- Elastic recovery (how well it bounces back)

- Seal geometry and design

- Part tolerances

- Temperature range

- Movement during use

The same hardness can work perfectly in one joint and fail completely in another.

Early Warning Signs:

Low squeeze problems (often too hard):

- Leaks at normal installation

- Not enough contact pressure

- Geometry doesn’t match

Over-compression problems (often too soft):

- Very high assembly force needed

- Seal takes permanent set quickly

- Excessive compression

How to Prevent:

Select hardness based on your specific application:

- Squeeze percentage available

- Contact width needed

- Tolerance stack-up in your assembly

- Temperature range

- Static vs dynamic movement

Test at least two hardness options in real joint conditions before finalizing. A prototype test is much cheaper than field failures.

Quick Troubleshooting: If Your EPDM Seal is Already Failing

If you’re facing an EPDM seal failure right now, here’s how to get help:

Share these 5 details:

- Service temperature range (normal and peak temperatures)

- Movement type (does it stay still or move?)

- Squeeze percentage or fit tightness

- Contact media (any cleaners, oils, adhesives, paints nearby?)

- Time to failure (failed on day 1, week 2, or month 6?)

With these details, an experienced seal manufacturer can identify the likely failure mode and suggest a fix.

Frequently Asked Questions About EPDM Seal Failures

Q: What is the most common cause of EPDM seal failure?

A: The most common cause is mismatch between design assumptions and real application conditions—especially incorrect squeeze percentage, thermal cycling effects, or under-cure in thick sections.

Q: How long should EPDM seals last?

A: Properly designed and manufactured EPDM seals typically last 10-20 years in outdoor weather sealing applications, and can last 25+ years in controlled environments.

Q: Can EPDM seals be used with oils?

A: Standard EPDM has poor resistance to petroleum oils. For oil contact, use NBR (Nitrile), FKM (Viton), or oil-resistant EPDM compounds specifically formulated for that purpose.

Q: What temperature can EPDM seals handle?

A: Standard EPDM works well from -40°C to +120°C continuously. Special compounds can handle up to 150°C for specific applications.

Q: How do I choose the right EPDM hardness?

A: Hardness should be selected based on squeeze percentage, seal geometry, tolerances, and temperature range—not just industry standards. Test in actual joint conditions.

Final Thoughts: Prevention is Cheaper Than Replacement

EPDM seal failure is frustrating, but it’s usually preventable.

The key is thinking about seals as complete systems, not just rubber parts. Match your seal design, compound, curing, installation, and environment to real working conditions.

If you’re designing a new sealing system or troubleshooting failures, here’s your action plan:

- Define real working conditions (temperature, squeeze, movement, chemicals)

- Test in conditions that match actual use, not just standard lab tests

- Validate cure quality in your actual production setup

- Design for proper installation (minimize stretch, avoid sharp edges)

- Consider chemical compatibility from all sources

- Select hardness based on joint physics, not just standards

Need help with a specific EPDM seal failure? Our team at Saga Elastomers has 30 years of experience troubleshooting seal problems across automotive, construction, solar, marine, and railway industries.

Contact us with your application details, and we’ll help identify the root cause and prevention approach for your specific case.

About the Author:

Milind Laddha is the Managing Director of Saga Elastomer Pvt Ltd, a rubber manufacturing company with three decades of experience in extruded and molded rubber solutions. SEPL holds ISO 9001:2015 and IATF 16949:2016 certifications and serves clients across automotive, Infra, pipe, mining, construction, marine, and railway industries.