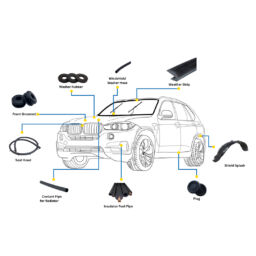

When it comes to advanced envelope design, the facade structures stand as the first line of defense against environmental forces. One critical yet often overlooked step in ensuring their long-term performance is implementing a preventive seal inspection for facades. While visible components like cladding panels and glass play a role, the rubber gaskets and profiles are the unsung heroes that protect against air and water leakage and support energy efficiency.

In this blog, we explore how preventative seal inspections help extend facade lifespan, reduce operating costs, and ensure consistent performance over decades.

Why Preventive Seal Inspection for Facades Is Essential

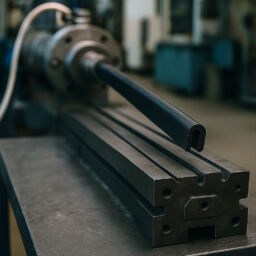

With the advancement of Construction and the building management ecosystem, rubber extrusion for facade systems is expected to do more than ever. Combatting extreme weather conditions, increasing thermal insulation, contributing to energy saving, indoor air quality, and long-term asset performance are among the basic requirements these days.

While the architectural appeal of facades always takes the center stage, the ultimate performance determinants are the hidden sealing components, especially rubber profiles and gaskets. Rubber seals in facades endure relentless environmental exposure:

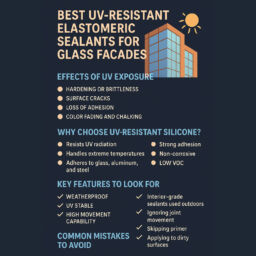

- UV radiation

- Ozone attack

- Thermal cycling

- Moisture and humidity

When left unchecked, these factors cause the rubber seals to harden, crack, and eventually fail, compromising the overall integrity of the facade.

Here is why a facade seal inspection plan is essential:

1. Buildings Are Now More Airtight and Energy-Sensitive

Due to the growing global emphasis on energy-efficient design and Eco-building certifications (such as LEED, WELL, and BREEAM), facades play a crucial role in energy conservation. Rubber gaskets play a pivotal role in sealing window panels, curtain walls, and structural joints to prevent unwanted air infiltration or conditioned air loss.

2. Intense Environmental Exposure

A change in climate has increased the environmental stresses on the building materials. Facades face prolonged sun exposure, more intense UV radiation, extreme temperature, higher rainfall and humidity levels than even a decade ago. In coastal or high-UV zones, seals endure even more stress due to salt spray, ozone, and solar radiation. If rubber profile inspection is missed or not upgraded periodically, they become highly vulnerable to this exposure.

3. Costs of Seal Failure Are Rising

Unlike a cracked panel or a broken window, which are immediately visible and often repaired quickly, seal failures are silent degraders. When facade rubber profiles fail, it allows moisture and air ingress into the facade silently. It starts as a minor seal failure and evolves into numerous repairs or disputes. The result is unusual spikes in financial and operational stakes, reaching alarming numbers for building owners and facility teams.

4. Costly and Disruptive Replacement

Replacing facade seals post-installation involves high-risk work, such as scaffolding, rope access, or the use of boom lifts, especially in high-rise structures. Contemporary facades are designed for energy performance and occupant comfort. A single compromised seal can lead to:

- Loss of thermal insulation and higher energy bills

- Air leakage affecting indoor air quality

- Premature corrosion of internal structural members

- Damage to high-end finishes and interiors

Yet, many maintenance teams still rely on reactive repairs, addressing the problem only after significant damage has occurred.

What Should a Preventive Seal Inspection Plan Include?

A well-structured inspection program is built on the principles of predictive maintenance, which involves identifying issues before they become failures.

1. Routine Visual Assessments

Conduct quarterly or bi-annual walkdowns to check for:

- Crack, brittle, or chalking of rubber gaskets

- Discoloration and UV damage

- Signs of compression set or shrinkage

- Water stains, condensation, or mould near glazing interfaces

The use of mobile inspection apps to log photographs, seal types, and the date of inspection comes as a rescue.

2. Moisture Testing

Use moisture meters or infrared thermography to identify hidden leaks behind panels or glazing before they become visible. Some leaks appear only under wind-driven rain conditions. Deploy scheduled facade spray tests to validate structural seal integrity.

3. Compression Set Monitoring

Over time, rubber loses its ability to spring back to its original shape after compression. If the seal remains flat or indented after pressure is removed, it has likely lost its sealing ability.

In complex applications, consider using sensor-embedded rubber profiles that monitor compression load and aging in real-time.

4. Accelerated Aging Comparison

Keep reference samples of the original gasket materials. Compare field samples removed from the facade against the original in terms of hardness, color, and flexibility. This provides a genuine insight into ageing.

How Often Should Seal Inspections Be Scheduled?

| Building Type | Inspection Frequency |

| Office/Commercial | Every 6–12 months |

| High-rise Residential | Every 12 months |

| Healthcare Facilities | Every 6 months |

| Coastal/Marine Environments | Every 3–6 months |

| Industrial Plants | Every 6 months |

Seasonal shifts also affect seals. Plan inspections just before the monsoon (in tropical zones) or after harsh winters (in cold regions).

Key Actions for Maintenance Teams

- Develop a Seal Registry – Document all rubber profiles in the facade, including dimensions, material type (EPDM, silicone), installation dates, and suppliers.

- Train Field Technicians – Train teams to recognize signs of degradation and empower them to collect field data consistently.

- Engage with Original Seal Manufacturers – Suppliers like Saga Elastomer offer testing support, replacement profile recommendations, and prototyping for retrofits.

- Maintain Stock of Critical Seals – For buildings with custom profiles, maintain a small inventory of replacement seals. Lead times can delay urgent replacements.

- Schedule Annual Review Meetings – Create a structured review with facility managers, contractors, and material suppliers to assess seal performance.

Predictive Maintenance with Smart Seals*

As facade systems become more complex and performance-driven, traditional seal inspections are no longer sufficient. Innovative rubber seals with smart monitoring capabilities are transforming building maintenance by leveraging predictive insights. They are no longer opting for reactive fixes. These advanced seals can be embedded with microsensors, color-changing indicators, or compression monitors to help facility teams track degradation and aging in real-time.

Key Benefits of Smart Facade Seals:

- Reduce Unpredicted Downtime: Identify seal degradation before the seal fails.

- Real-Time Monitoring: Track UV exposure, compression set, and environmental stress through installed sensors

- Enable Scheduled Replacements: Plan seal upgrades and replacements during routine maintenance windows to ensure seamless operation.

- Performance Track: Optimize maintenance budgets and service intervals by using analytics through integrated sensors and apps.

- Meet Eco-Construction Goals: Minimize waste by prioritizing only the necessary items.

- Enhance Facade Reliability: Extend the lifespan and resilience of curtain wall systems.

*This is a concept yet and we do not have any expertise of this seal .

Scheduled inspection plans identify the immediate issues along with the upcoming replacements over the next 3 to 5 years. This allows for:

- Budget planning

- Reduced emergency repairs

- Less tenant disruption

- Opportunity to upgrade to smarter, longer-life profiles

Comparing the ROI of the Preventive Seal Inspection Plan Vs No-Plan

| Metric | Without Plan | With Inspection Plan |

| Annual Maintenance Costs | ₹4–6 Lakhs | ₹1–2 Lakhs |

| Water Damage Repair Risk | High | Low |

| Energy Efficiency Degradation | Moderate | Minimal |

| Emergency Downtime | Frequent | Rare |

| Facade Lifespan | 8–10 years | 15–25 years |

Therefore, rubber seals may be small, but their impact on the lifespan, safety, and efficiency of a facade system is massive. A preventative seal inspection plan helps extend service life, maintain performance, and reduce long-term costs.

Saga Elastomer is your trusted partner for high-performance facade rubber profiles, inspection support, and lifecycle extension planning.

How Saga Elastomer Supports Inspection?

At Saga Elastomer, rubber profile compounds are optimized for outdoor exposure utilizing carbon black, UV-resistant rubber seals, and precise cross-linking, certified under ISO 4892 accelerated weathering tests with scheduled EPDM rubber profile maintenance.

We partner with maintenance teams, facade consultants, and property owners, supporting them with:

- Technical consultation for seal specification and aging assessment

- Custom rubber profile matching for existing designs

- UV/weather test reports for inspection audits

- Tooling and rework of discontinued profiles

- Training workshops on facade gasket inspection techniques and lifecycle extension