In the rapidly advancing automotive industry, establishing supply chain resilience is no longer a “nice-to-have” — it’s an operational imperative. Factors such as semiconductor shortages, natural disasters, and regional lockdowns have highlighted the weaknesses of depending on a single source for critical automotive components.

The leading Original Equipment Manufacturers (OEMs) nowadays opt for a dual sourcing strategy, partnering with Tier 2 automotive suppliers to maintain a smooth supply chain process. Dual sourcing for automotive suppliers supports production continuity, underpins quality improvement, encourages competitive pricing, and drives innovation.

For export-oriented Tier 2 automotive manufacturers, the focus on the dual sourcing strategy brings both challenges and opportunities. They are expected to deliver technically excellent rubber components and demonstrate robust manufacturing processes and certifications. So, there is a higher demand for credible secondary sources of automotive parts in the industry.

- The strategic and significant determinants that unveil the reason why OEMs want dual-source suppliers

- The risks of dependence on a single‑supplier

- Critical compliance benchmarks

- Saga Elastomer’s dual‑sourcing capabilities and supporting services

- Onboarding Saga Elastomer as your compliant second rubber supplier

- Advantages of Dual Sourcing

1.1 Rising Demand for Supply Chain Resilience

In the past few years, automotive production has been repeatedly derailed by some of the inevitable forces:

- COVID-19 lockdowns had resulted in plant closures in the key manufacturing hubs, creating backlogs in component manufacturing and deliveries.

- Geopolitical tensions increased delivery lead times of raw materials such as EPDM and NVH rubber components.

- Extreme weather changes (floods, wildfires, hurricanes) hindered regional logistics networks.

A single instance of unplanned outage at one plant can have a major impact on entire vehicle production lines, with OEMs estimating losses of millions of dollars per hour in assembly downtime. Anticipating this risk and to build resilience, OEMs now mandate at least two automotive component suppliers with global OEM compliance standards, for each critical component, ensuring seamless production for business continuity.

1.2 Benefits Beyond Business Continuity

Automotive dual‑sourcing strategy brings in several advantages beyond simple global sourcing risk mitigation:

- Cost Optimization: Hiring two suppliers unlocks and strengthens economies of scale.

- Innovation Acceleration: Secondary sources often enlarge the scope of sourcing alternative materials or process improvements, and competitive advantage.

- Capacity Flexibility: OEMs can increase their volumes quickly without weighing down any single production line.

- Audit Readiness: OEMs can smoothly monitor suppliers, maintaining high-quality standards, which prepares them for audits.

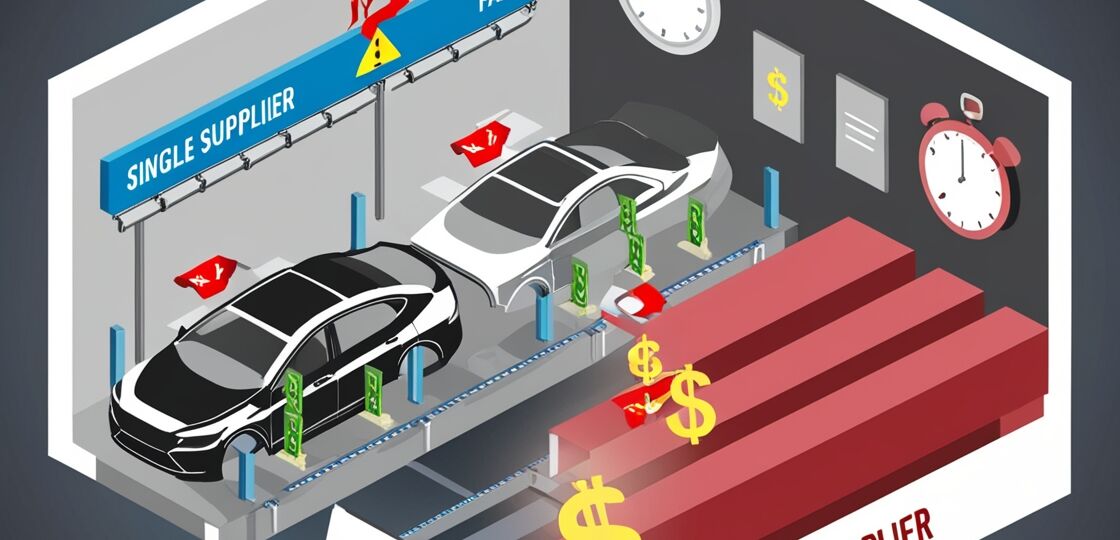

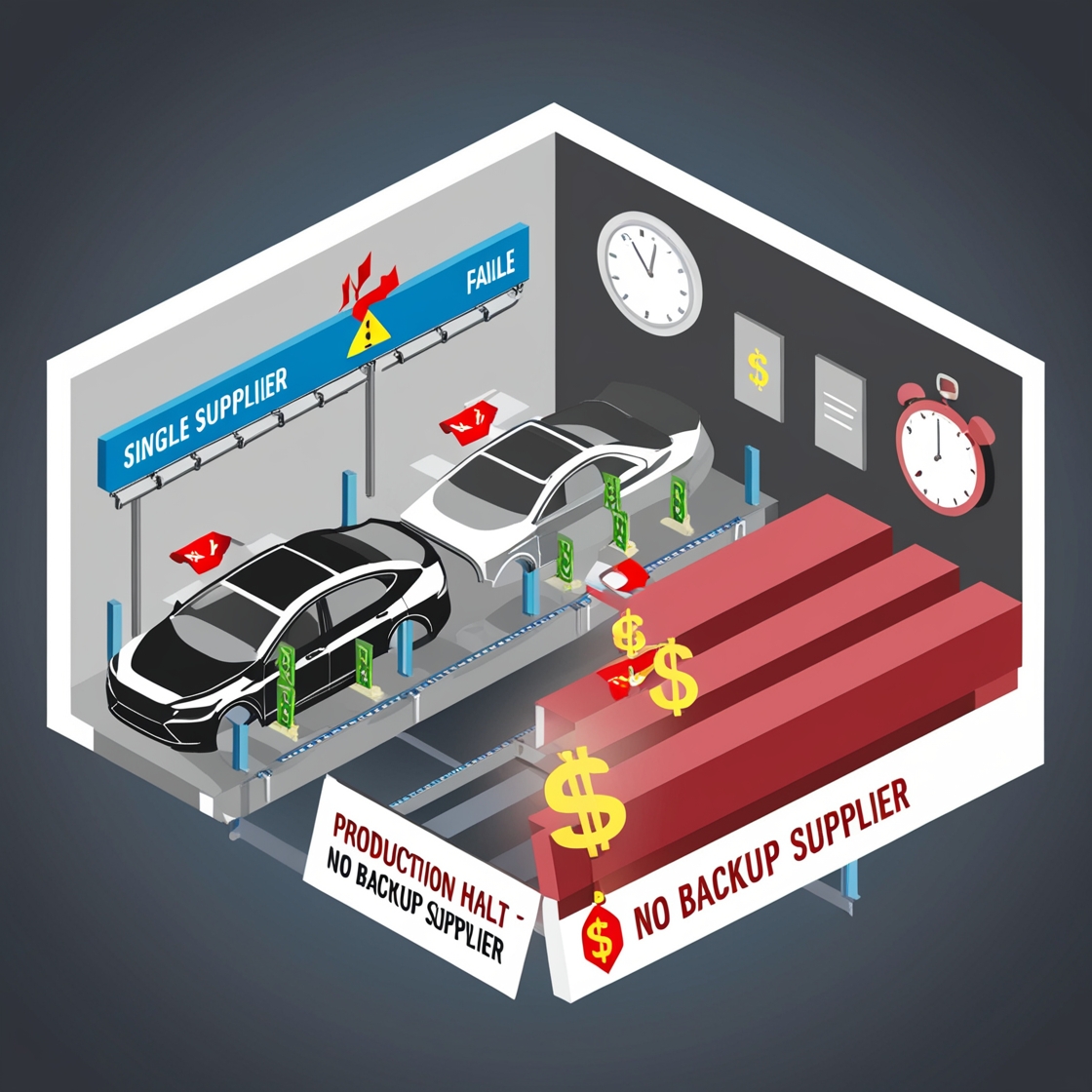

- Disadvantages of Single‑Supplier Dependence

2.1 Production Halts and Penalties

Relying on a single supplier for automotive components like EPDM sponge, NVH rubber, etc, invites significant risks:

- Production and Line Delays: Any manufacturing constraint, quality issue, or other inevitable conditions impacting the single source can cause massive delays in the automotive assembly.

- Penalties under Agreements: OEMs and automotive manufacturers often incur financial penalties under Just‑In‑Time (JIT) supply agreements.

- Emergency Premiums: When the primary supplier fails to deliver components on time, urgent air‑freight or local re-sourcing shoots up the production and the supply chain budgets.

2.2 Quality & Compliance Exposures

- Process Changes: Factors like changes in production process, raw material shifts, etc., at the primary supply source may slip through the quality controls. It may only surface during OEM PPAP testing. This results in rejections, rework, and strained relationships.

- Regulatory Non-Compliance: If the single supplier’s batch fails to meet the REACH or RoHS standards, it impacts and holds the downstream program until the remediation is achieved.

Top-tier OEMs continuously strive to avoid such scenarios and depend on flawless supplier performance to maintain a strong brand reputation and ensure regulatory compliance.

- How to Qualify a Second Rubber Supplier?

To satisfy dual‑sourcing requirements, every supplier must meet or exceed the critical compliance benchmarks and the demanding set of global standards:

| Standard / Requirement | Purpose |

| IATF 16949 | Automotive quality management, ensuring defect prevention and full traceability across the processes |

| ISO 9001:2015 | Core quality system certification, demonstrating consistent manufacturing and continual improvement |

| FMVSS 302 | U.S. flammability standard for interior materials, mandatory for suppliers to North American OEMs |

| REACH & RoHS | European chemical safety regulations governing use of restricted substances and material disclosures |

| PPAP & APQP Documentation | Structured process for part approval, including PSW, ISIR, Control Plans, FMEAs, and MSA |

| IMDS Reporting | Standardized database for tracking material composition in automotive parts |

For Tier 2 automotive suppliers, it is mandatory to supply complete documentation packages, pass stringent audits, and provide ongoing traceability from raw materials to shipment, along with producing a compliant part.

- How Saga Elastomer Fulfills Dual‑Source Mandates for Global OEMs?

4.1 Robust Quality Management: IATF 16949, ISO 9001:2015, IRMRA

- The manufacturing facilities of Saga Elastomer operate under ISO 9001:2015 guidelines, with a dedicated quality assurance (QA) team implementing six‑sigma and lean

- We are in the final stages of IATF 16949 certification, aligning with OEM expectations for automotive-grade quality, continuous improvement, and risk management.

- As a testament to our commitment to quality and reliability, we present our Test Reports for Rubber Tire Flap, conducted by the Rubber Manufacturers Research Association (IRMRA), and Test Reports certifying our EPDM Gasket sample and deemed with Grade “A” rating from the Engineering Research Center of the Central Institute of Road Transport, India.

4.2 Comprehensive Documentation & Support

- PPAP & APQP Kits: We provide supporting documentation — including Part Submission Warrant (PSW), Failure Mode and Effects Analysis (FMEA), Initial Sample Inspection Reports (ISIR), Measurement System Analysis (MSA), and Control Plans — to streamline OEM approvals. (Please remove if not applicable)

4.3 Global Export Capabilities

- HS Code Compliance: We export under HS Codes – 40082990, 40061090, 40081990, 40169990, and related codes, with customs documentation for various markets including the USA, EU, GCC, Australia, Taiwan, and South Korea. (Please remove if not applicable.

- Strategic Warehousing: Saga maintains a safety stock with a scalable production capacity to facilitate seamless demand surges.

4.4 Sustainability & Risk Management

- REACH/RoHS Compliant Compounds: We have qualified the Restriction of Hazardous Substances (ROHS), complying with ROHS Directive 2011/65/EU, and ROHS 10E, verifying our EPDM Sponge Tube.

- Green Manufacturing Initiatives: We employ energy-efficient extrusion processes and implement waste reduction programs to minimize our carbon footprint and align with the sustainability goals of our OEMs. We have installed rooftop solar panels to contribute to clean energy.

Onboard Saga Elastomer as Your Trusted Second Rubber Supplier

To transform your dual sourcing strategy from theory to practice:

- Contact our Automotive Team: Discuss your part requirements and timelines.

- Request a Dual‑Source Proposal: We’ll outline MOQ options, standard lead times, and certification/test reports.

- Start Sample Approval: Get automotive rubber sample parts and documentation kits to start your PPAP process.

- Implement Safety Stock & Logistics Plans: Ensure immediate availability of parts.

Don’t jeopardize your production schedules or program launches by depending on a single supplier.

Strengthen your supply chain with Saga Elastomer’s IATF-compliant, ISO certified, and fully documented dual-source solutions.

🔹 Get IATF‑Compliant Dual Source Support

🔹 Book a Call with our automotive experts today

📩 Email: [email protected]

🌐 See Our Products: https://www.sagaelastomer.com/industries/automotive-industry/

Follow us on linkedin