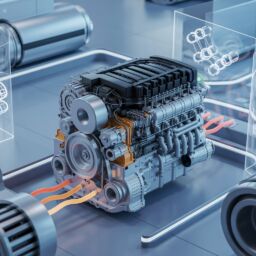

In the automotive industry and its supply chain, Tier 2 suppliers face mounting pressure to deliver high-performance HVAC rubber components with zero delays. HVAC rubber insulation for air ducts and dampers must be precise, consistent, and ready for immediate assembly. Every hour of delay or mismatch in tooling and extrusion can ripple into costly production line stoppages and OEM penalties.

Saga Elastomer, an ISO 9001:2015 and IATF 16949 certified rubber manufacturer headquartered in Palghar, Maharashtra, understands this pressure. With in-house HVAC rubber tooling support, extrusion, and continuous vulcanization capabilities, Saga bridges the gap between rubber engineering and production delivery, minimizing lead times and quality risks for global automotive clients.

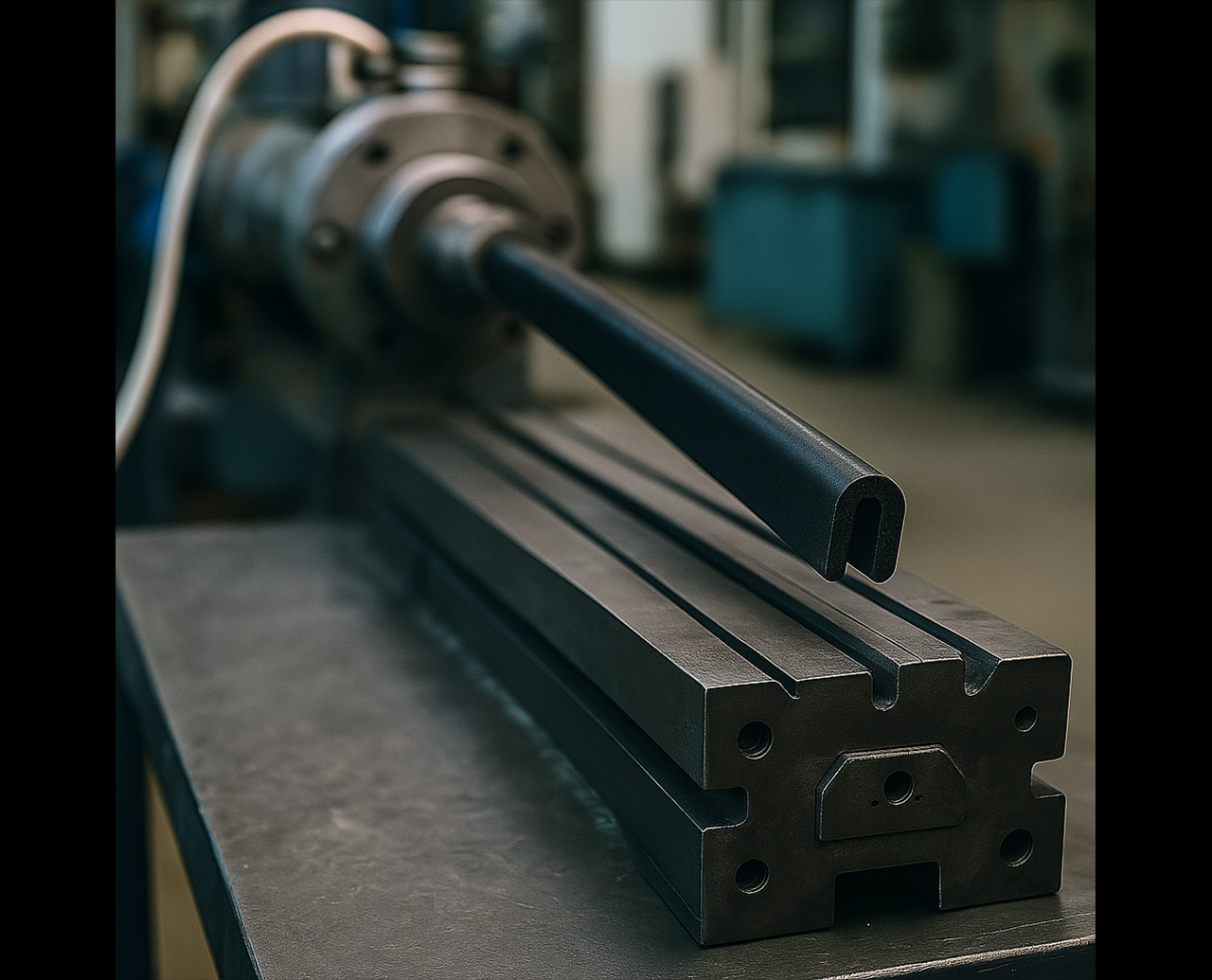

Why Tooling Matters in HVAC Rubber Extrusion?

1. Tight Tolerances, Zero Play

HVAC duct components often need to snap-fit or bond within millimetres of precision. Metal clamps, foil tapes, and assembly jigs rely on the exact density and geometry of rubber. Even minor deviations can lead to:

- Assembly delays

- Poor fit or air sealing issues

- NVH (Noise, Vibration, Harshness) nonconformance

- Rework and scrap during PPAP

Effective tooling ensures that every meter of material matches the CAD design, from the extrusion die to the finished product.

2. Speed-to-Market with Prototypes

Without in-house tooling, many suppliers wait weeks for dies to be manufactured. That delay cascades into lost test cycles, delayed validation, and missed launch dates.

Saga Elastomer eliminates this lag by combining tooling design, extrusion, and vulcanization within its facility, helping OEMs iterate automotive HVAC prototype tooling and finalize specifications rapidly.

Saga Elastomer’s Tooling & Production Capabilities

- In-House Tooling Design

Saga employs seasoned engineers who understand automotive HVAC requirements. From CAD designs to CNC tool fabrication, every rubber extrusion die is optimized for shape accuracy, compound flow, and longevity. - Quick-Turn Tropical Die-lines

For prototypes and short launches, Saga can produce tooling in days, allowing for the production of validation samples within the same week. - Continuous Vulcanization

Saga’s extrusion lines are backed by continuous vulcanization tunnels, which deliver consistent cured profiles, stabilized cross-linking, and minimal post-processing, eliminating manual cure variability. - Integrated QC Labs

Built right into the production environment, QC labs measure:- Dimensional accuracy within ±0.1 mm

- Tensile strength and elongation

- Compression set for HVAC sealing

- Temperature and ozone stability

Every profile is batch-numbered, making it ideal for PPAP documentation.

- Certifications Backing It Up

Under ISO 9001 and automotive-grade IATF 16949 certified rubber tooling, Saga maintains traceability from tooling batch to shipment. This integrated control ensures that OEMs can trace specifications and compliance if any issues arise down the line.

How does this Reduce Production Delays?

In the automotive HVAC ecosystem, production schedules are rigid, and OEM scorecards are unforgiving. A delay in even the smallest rubber component—such as an HVAC duct seal or sponge insulation wrap—can trigger missed shipment windows, expedited logistics costs, or worse, line stoppages. Saga Elastomer’s in-house tooling and extrusion integration directly addresses these risks by streamlining the design-to-delivery cycle.

1. Faster Prototype Development

With most suppliers, tooling alone can take 3–4 weeks before you even see a prototype. Saga shortens that drastically. Thanks to their in-house tool room and CAD-CAM capabilities, dies for rubber profiles can be developed, tested, and extruded within a matter of days. This enables:

- Quicker physical validation of parts in HVAC assemblies

- Early NVH testing under airflow and vibration

- Faster iterations for wall thickness, density, or durometer adjustments

Suppliers often fail to meet tight timelines for pre-launch samples and PPAP submissions, ensuring the component qualifies well ahead of the production start date.

2. Avoidance of Supply Chain Downtime

Third-party sourced dies often cause a lag during tooling maintenance or duplication. Saga mitigates this by:

- Creating a backup dies in-house for high-volume programs

- Reconditioning damaged dies without external dependencies

- Offering on-demand retooling for urgent batch restarts

This agility ensures continuous supply, particularly for HVAC programs with high seasonality or export demands.

3. Eliminating Batch Inconsistencies

Rubber extrusion tolerances are highly dependent on tooling alignment, die quality, and compound flow. When tooling and production are done in separate locations, inconsistencies creep in, resulting in:

- Out-of-spec wall thickness

- Uneven surface finish

- Variable sponge density or compression set

Saga’s single-site model, where tooling, extrusion, and quality control operate in sync, guarantees dimensional consistency, surface finish uniformity, and mechanical integrity in every extrusion. It helps to lower reworks and rejections while ensuring uncomplicated product assemblies.

4. Design Changes

HVAC suppliers frequently need to respond to design updates, such as changes in radius, cross-sections, or modified foam densities. Depending on third-party suppliers causes:

- Rework delays

- Misalignment in version control

- Unexpected revalidation process

At Saga, the tooling revisions are conducted on-site, within 24–72 hours. It supports automotive suppliers in adapting to design changes with minimal disruption and meeting revised OEM specifications without affecting line readiness.

5. Streamlined Documentation for OEMs

A fully traceable documentation process supports Saga’s tooling. Every extrusion batch is tied to a unique tool ID, raw material lot, and process control chart. This enables:

- Faster completion of PPAP, ISIR, and FAI submissions

- Easier root-cause tracking in case of quality queries

- OEM confidence during audits or spot inspections

As a result, automotive HVAC suppliers save precious time during launch reviews, quality escalations, and RFQ win-backs.

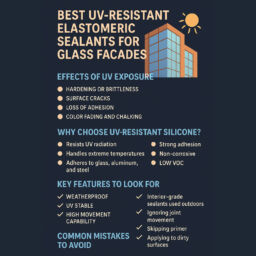

Actionable Insights for Automotive HVAC Suppliers

If you’re sourcing EPDM sponge or custom insulation parts, here’s how Saga Elastomer’s tooling support can benefit you:

| Challenge | Impact on Supplier | Saga Elastomer Solution |

| Prototype delays | Risk of missing validation deadlines | On-site tooling and fast prototype runs |

| Batch variability | Lot rejection or audit holds | Consistent extrusion with QC documentation |

| Tool mismatches | Increased scrap and restarts | In-house tooling updates and spare dies |

| OEM Scorecard dips | Risk of losing future work | IATF 16949 backed consistency assurances |

| Volume surge | Supply chain interruption | On-site scale-up with duplicate tooling |

Why Saga Is the Right Partner

In today’s highly competitive automotive landscape, Tier 2 suppliers must exceed the expectation of meeting just specs. They must anticipate problems before they arise, adapt quickly, and deliver consistently. This is where Saga Elastomer stands out as a rubber extrusion vendor and a strategic manufacturing partner.

1. Fully Integrated Tooling, Production, and QC Ecosystem

Unlike fragmented supplier setups, where tooling is outsourced and production is disconnected from design, Saga brings all critical stages – tooling design, die manufacturing, rubber compounding, extrusion, curing, and quality control under one roof. This integration results in:

- Faster turnaround times from drawing to production

- Seamless communication between tooling and production teams

- Elimination of mismatch or miscommunication delays

This vertical integration enables Tier 2 suppliers to confidently plan their delivery schedules without fear of last-minute changes or bottlenecks.

2. IATF 16949 & ISO 9001:2015 Certified

OEMs demand compliance with global automotive standards, and Saga delivers on this expectation. The company’s IATF 16949 certification ensures that every aspect of production—from raw material selection to process documentation—is traceable, controlled, and audit-ready. Benefits include:

- Reduced risk of supplier disqualification

- Faster PPAP approvals and quality validation

- Confidence during OEM audits or quality escalations

For procurement heads and QA managers, this certification helps to lower the risk of supply chain disruptions.

3. Expertise in HVAC Rubber Applications

Saga possesses in-depth domain knowledge in EPDM sponge extrusion tooling, rubber extrusions, and vehicle window sealing profiles, which are explicitly used in automotive HVAC systems.

Benefits are as below:

- Engineering recommendations based on airflow, NVH, and thermal behavior

- Compatibility with duct materials like aluminium, plastic, or fiber-reinforced composites

- Support in selecting the proper durometer, density, and wall thickness for performance

Suppliers working on cold-air ducting, drain tubes, or NVH insulation benefit from Saga’s focused expertise in rubber, not just material delivery.

4. Tailored Compound Formulations

Saga’s in-house compounding facility provides them with complete control over the chemical formulation of their rubber materials. This allows them to:

- Develop custom EPDM blends with precise control over compression set, aging, and ozone resistance

- Adjust formulations to suit specific climatic zones or export market regulations (e.g., REACH, RoHS) to ensure compliance with relevant regulations.

- Ensure repeatable compound quality even in large-volume orders.

This is especially valuable for HVAC programs where sponge consistency, thermal insulation, and material flexibility determine the end performance.

5. Rapid Prototyping and Revision Cycles

Saga understands the importance of launching schedules on time. The tooling and process teams are structured to:

- Turn around prototype tooling in days, not weeks

- Create sample quantities for fitment checks, NVH testing, and validation

- Adapt swiftly to OEM-suggested revisions during the development phase

This shortens product development cycles and supports Tier 2 suppliers competing in RFQs with tight launch windows.

6. Proven Track Record with Export-Oriented Programs

Saga’s rubber components are already supplied to HVAC and sealing solution providers in Europe, the USA, South Korea, the Middle East, and Australia. Their familiarity with:

- Global shipping logistics

- Export packaging standards

- Regulatory documentation

makes Saga a reliable partner for suppliers catering to export-heavy OEM platforms or multi-regional JVs.

7. Commitment to Communication and Support

Saga Elastomer’s principle is built on transparency, team collaboration, and lean process, translating into:

- Proactive updates on tooling and batch status

- Collaborative problem-solving during development hiccups

- Consistent follow-through from order to dispatch

Tier 2 suppliers frequently cite Saga’s reliability, responsiveness, and engineering depth as reasons for long-term collaboration.

From Delays to Delivery: How Saga Reduces Time, Cost & Risk

By integrating tooling with extrusion, Saga helps automotive HVAC component suppliers to reduce:

- Up to 50% of the prototype lead time

- Batch variability-related rejects by 60%

- Line stoppages due to seal failure risk

- Time spent on documentation and audit readiness

All of this translates to better OEM scorecards, stronger sourcing relationships, and higher contract win rates under Just-In-Time schemes.

Next Steps: How to Engage Saga Elastomer

- Initiate a Technical Call: Share your HVAC part specs, CAD files, and forecasted volumes.

- Prototype & Tooling Quote: Receive rapid tooling timelines and sample schedule

- Design Iteration Support: Get design feedback and fit validation advice early

- PPAP-Ready Production: Begin production with complete documentation and quality control

Whether you’re launching an HVAC duct for ICE or EV platforms, Saga Elastomer’s tooling-first strategy ensures your rubber insulation hits every milestone on time and in full.