Getting the Right Seals and Making Them Last

In Part 1, we covered why hatch seals fail and how to avoid the most common installation and material mistakes. Now let’s tackle something equally important but often misunderstood: how to actually get the right seals for your vessel, what certifications matter (and which are just paperwork), and the maintenance practices that turn a 5-year seal into a 15-year seal.

Understanding Certification: What Actually Matters

Walk through any procurement department and you’ll hear about ISO this, IATF that, and a dozen other acronyms. But here’s what most people don’t realize: not all certifications are equally important for marine seals, and some that sound impressive mean very little for your specific application.

The Certifications That Actually Protect You

ISO 9001:2015 isn’t just paperwork—it’s your guarantee that the seal manufacturer maintains consistent quality. What this really means: Every batch of seals you order will have identical material properties, dimensional accuracy, and performance characteristics. For maintenance planning, this consistency is everything. You can confidently stock replacement seals knowing they’ll perform identically to the ones currently installed.

IATF 16949:2016 goes beyond ISO 9001, indicating advanced manufacturing capabilities particularly relevant for custom seals requiring tight tolerances. If your vessel has unique hatch designs or you’re ordering seals with dimensional tolerances under ±0.5mm, this certification matters. It means the manufacturer has the quality systems and measurement capabilities to deliver what you’ve specified.

The Certification Gap Most People Miss

Here’s something important: General quality certifications don’t tell you whether a seal actually works in marine conditions. A manufacturer can have perfect ISO certification and still use rubber compounds that degrade rapidly in saltwater.

When evaluating seal suppliers, ask these specific questions:

- Do you have documented salt spray testing results showing resistance for 1,000+ hours?

- What’s your UV exposure testing protocol, and can you share results?

- Have you tested compression set at elevated temperatures matching our operational conditions?

- Can you provide samples for our own validation testing?

If a supplier hesitates on any of these, that’s your answer. Quality manufacturers will share performance data because they’ve actually tested their products in conditions matching your application.

When You Need Custom Seals (And How to Get Them Right)

Sometimes off-the-shelf seals simply won’t work. Understanding when you need custom seals—and how to specify them properly—saves enormous time and money.

Five Situations That Demand Custom Solutions

- Legacy Vessel Seals with No Manufacturer Information

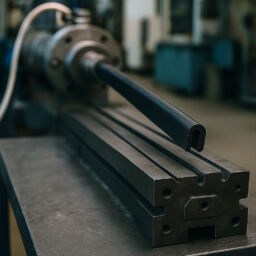

You’ve inherited a vessel. The hatch seals are deteriorating, but there’s no documentation about specifications, and the original manufacturer is long gone. The existing seal profile doesn’t match anything in current catalogs.What to do: Create a comprehensive profile specification. Use calipers to measure the cross-section at multiple points—seals deform over time, so measure undamaged sections. Make a clay impression of the profile if the shape is complex. Photograph the installation from multiple angles showing how the seal sits in the groove and contacts the hatch.

Send this package to potential manufacturers with operational details: temperature range, chemical exposures, salt spray exposure, UV exposure level, and how frequently the hatch opens. A competent manufacturer can reverse-engineer the seal and often improve upon the original design.

- Extreme Environmental Conditions

Your vessel operates in Arctic waters where temperatures hit -40°C, or in regions with intense UV exposure combined with extreme temperature swings.Standard marine seals are typically specified for -20°C to +80°C. Operating outside these ranges requires custom compound formulation. Be specific about your extremes: “We need seal function at -40°C with hatch operation possible after 30 minutes exposure” is actionable. “Cold weather operation” is not.

- Unusual Chemical Exposures

Your vessel carries specialized cargo or uses specific cleaning protocols that expose seals to chemicals not covered by standard marine formulations.Provide actual chemical names and concentrations, not generic descriptions. “Resistant to cleaning agents” doesn’t help. “Must resist weekly exposure to 5% sodium hypochlorite solution” gives manufacturers what they need to formulate appropriate compounds.

- High-Frequency Operation

Most marine hatch seals are designed for occasional operation—opened daily or weekly. If your application involves multiple openings per hour, standard seals will fail through mechanical fatigue.Specify your operational cycle: “Hatch opens/closes 20 times per day, 250 days per year.” This allows manufacturers to recommend materials with appropriate fatigue resistance and potentially suggest profile modifications that reduce wear.

- Aesthetic Requirements Combined with Performance

Luxury yacht builders face a challenge: seals must be functionally excellent while minimally visible.This typically requires custom low-profile designs, often in specific colors. Be clear about both requirements: “Need watertight performance to 0.5 bar pressure differential with seal visible height under 5mm in RAL 7011 grey.” Good manufacturers can work within these constraints, but they need complete specifications upfront.

The Smart Way to Request Quotes and Samples

Getting the right seal at a fair price requires more than firing off a quick email saying “need hatch seals.” Here’s the process that actually works:

Step 1: Document Everything That Matters

Create a specification sheet including:

Physical Requirements:

- Cross-sectional profile (with diagram or photo)

- Length/perimeter needed

- Dimensional tolerances you can accept

- Material hardness range (Shore A)

Environmental Conditions:

- Minimum/maximum operating temperatures

- Chemicals that might contact the seal

- UV/ozone exposure level (external vs. internal hatches)

- Saltwater/freshwater exposure

Performance Requirements:

- Compression requirements (% of original thickness)

- Expected pressure differential the seal must withstand

- Required service life

- Frequency of hatch operation

Quantity Requirements:

- Initial installation quantity

- Annual replacement estimate

- Preferred ordering quantities

Step 2: Select Qualified Manufacturers

Don’t just search “marine seal suppliers” and email everyone. Qualify manufacturers before requesting quotes:

- Verify they have ISO 9001:2015 or equivalent quality certification

- Confirm they manufacture in the materials you need (don’t assume all rubber suppliers work with all compounds)

- Check if they have custom manufacturing capabilities or only sell standard profiles

- Ask about minimum order quantities—some manufacturers only handle large commercial orders

Step 3: Request Samples Before Committing

Never order production quantities without testing samples in your actual application. When requesting samples:

“We’d like to evaluate 2 meters of seal material in your recommended compound for the following application: [provide conditions]. We’ll test for dimensional fit, compression characteristics, and preliminary weathering. What’s your sample policy?”

Most manufacturers provide samples at nominal cost or free for serious commercial applications. If they won’t provide samples, find a different supplier.

Step 4: Validate Samples Properly

When samples arrive, don’t just look at them. Test them:

- Install on actual equipment (or representative mockup)

- Verify dimensional fit and compression

- Check ease of installation

- Test hatch operation under load

- If possible, expose samples to your operational conditions (salt spray, UV, temperature cycling) for accelerated testing

Document everything. Photos showing proper fit or identifying issues become valuable references for discussions with the manufacturer.

Step 5: Discuss Technical Questions Directly

Email specifications, but have a conversation for critical applications. A 15-minute call with a manufacturer’s technical team often reveals solutions you hadn’t considered:

- Alternative materials you might not have specified

- Design modifications that improve performance or reduce cost

- Installation tips specific to your application

- Realistic service life expectations

Maintenance That Actually Extends Seal Life

You’ve got the right seals installed properly. Now let’s talk about making them last twice as long as typical service life.

The Monthly Cleaning Protocol That Matters

Salt accumulation is the silent killer of marine seals. Even small salt deposits create stress points that accelerate cracking. Here’s the effective cleaning protocol:

Tools needed: Soft brush, bucket with fresh water and mild marine detergent, clean towels, marine seal conditioner (silicone-based or manufacturer-recommended).

Process:

- Open the hatch fully and remove any debris from the seal groove

- Mix warm fresh water with marine-safe detergent (avoid harsh cleaners)

- Scrub the seal gently with the soft brush, paying special attention to folds and corners

- Rinse thoroughly with fresh water—salt residue accelerates degradation

- Dry completely with clean towels

- Apply thin coat of marine seal conditioner following product directions

Time required: 5-7 minutes per hatch

Result: This simple routine removes salt deposits before they cause damage, keeps seals supple, and extends service life by 50-100%.

The Inspection Routine That Catches Problems Early

Monthly cleaning is when you perform your visual inspection. Look for these warning signs:

Surface cracking: Fine cracks perpendicular to seal length indicate ozone or UV damage starting. Document and monitor. Replace if cracks extend deeper than 1mm.

Hardening: Press the seal with your thumb. It should compress easily and bounce back immediately. If it feels hard or returns slowly, the material is degrading. Check hardness with a durometer if you have one—a 10-point increase in Shore A hardness indicates significant degradation.

Compression set: Look at the seal profile when the hatch is open. Does it return to its original shape within 30 seconds? If permanent deformation exceeds 25% of original thickness, schedule replacement.

Corner separation: Check every corner and joint. Any visible gap or separation needs immediate attention. Small separations become major leak points rapidly.

Discoloration: Significant color changes (not just dirt) often indicate chemical attack or UV degradation affecting material properties.

The Storage Practices That Prevent Premature Aging

Spare seals sitting on shelves can degrade before you install them. Proper storage doubles shelf life:

Environment: Store in cool (15-25°C), dark location away from ozone sources (electric motors, welding equipment). Avoid areas with significant temperature fluctuation.

Position: Store seals flat or in large-diameter coils—never folded or kinked. Small-diameter coiling creates permanent deformation.

Protection: Keep seals in sealed bags or containers to prevent ozone and UV exposure. Don’t store near solvents, fuels, or strong chemicals—vapor exposure causes degradation.

Inventory rotation: Mark storage date on all seals. Use FIFO (first in, first out) inventory management. Even properly stored seals degrade over time—rubber compounds have finite shelf life.

For EPDM seals: 5-year shelf life with proper storage For Silicone seals: 7-10 year shelf life For NBR/Nitrile seals: 3-5 year shelf life For Viton/FKM seals: 10+ year shelf life

Troubleshooting: When Things Go Wrong

Despite best efforts, problems happen. Here’s how to diagnose and fix common issues:

Problem: New seal leaks immediately after installation

Likely causes:

- Insufficient compression (seal too thick for groove depth)

- Contaminated sealing surfaces

- Corner joint failure

- Hatch frame misalignment

Diagnosis: Open hatch and examine seal. Look for even compression marks around entire perimeter. Uneven marks indicate alignment issues. No compression marks in sections indicate insufficient compression.

Fix: Verify seal dimensions against groove specifications. Check frame alignment with straight edge. Clean and reinstall with proper compression verification.

Problem: Seal works initially but fails within 6-12 months

Likely causes:

- Wrong material for environmental conditions

- Chemical incompatibility

- Excessive UV/ozone exposure without protection

- Temperature cycling beyond material capability

Diagnosis: Examine failed seal. Surface cracking indicates UV/ozone damage. Swelling or material softening indicates chemical attack. Hardening indicates heat exposure or material degradation.

Fix: Identify the specific environmental challenge and specify appropriate material. Surface treatments or operational changes may also help.

Problem: Inconsistent sealing—sometimes leaks, sometimes doesn’t

Likely causes:

- Marginal compression (seal is borderline too thick/thin)

- Developing compression set

- Pressure cycling causing seal movement

- Corner joint partially failed

Diagnosis: This is trickier. Inspect during both leak and no-leak conditions if possible. Focus on corners and areas where seal may shift under pressure.

Fix: Often requires replacing with properly sized seal and ensuring corners are properly joined or molded.

Making Smart Long-Term Decisions

The difference between vessels with chronic seal problems and those with reliable hatch integrity often comes down to systematic decision-making:

Build a seal specification database: Document every seal on your vessel—material, dimensions, manufacturer, installation date, replacement date. This historical data helps predict replacement needs and identify problematic applications.

Plan replacements proactively: Don’t wait for failure. Based on inspection data and manufacturer recommendations, schedule seal replacements during planned maintenance. This costs less and avoids emergency repairs.

Standardize where possible: If you can use the same seal material and profile across multiple hatches, do it. This simplifies inventory, training, and maintenance.

Invest in quality: Premium marine-grade seals cost 30-50% more than generic options. But they last 2-3 times longer and fail less frequently. The lifetime cost is actually lower.

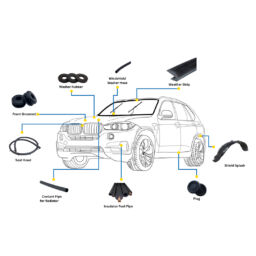

Work With a Manufacturer Who Gets It

At Saga Elastomer, we manufacture custom and standard extruded rubber seals including hatch seals, cabin seals, chords, fenders, and bumpers specifically for marine applications. Our IATF 16949:2016 and ISO 9001:2015 certified facility in Palghar produces seals in EPDM, NBR, Silicone, Neoprene, and FKM compounds engineered for harsh marine environments.

With 30 years of experience and 75+ metric tons monthly production capacity, we handle everything from small yacht builders to commercial shipbuilders requiring large volumes.

More importantly, our engineering team understands that every vessel faces unique challenges. Whether you’re replacing legacy seals with no documentation, designing custom solutions for specialized vessels, or simply need reliable supply of quality marine seals, we work with you to develop solutions that actually work in your operational environment.

Get in touch with Team Saga to discuss your seal requirements. We’ll help you specify the right materials, provide samples for validation testing, and develop a supply relationship that ensures you have the seals you need when you need them.

Contact us at: [email protected]