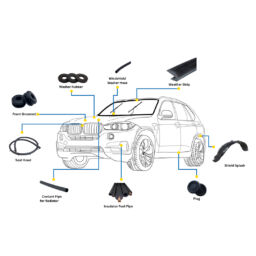

When automotive manufacturers test for cabin comfort, one key factor often being scrutinized is NVH, which stands for Noise, Vibration, and Harshness. With the rise of EVs, vehicles have become quieter. Small acoustic leaks or vibrations that once went unnoticed now make the difference between passing or failing on the OEM scorecard.

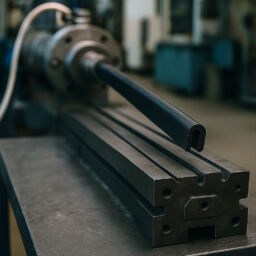

A critical, yet underestimated component in this equation is the rubber HVAC insulator, made from EPDM sponge rubber. In Tier 2 automotive supply chains, where HVAC ducting, air channels, and thermal insulation parts are generally outsourced, the quality of the EPDM sponge rubber can significantly impact NVH ratings.

Let’s explore why NVH performance matters and how sourcing decisions at various levels can affect your downstream relationships with global OEMs.

Why is NVH Significant for Automotive Manufacturers?

For automotive OEMs, NVH performance is a benchmark of quality and refinement. Especially in EVs and high-end passenger vehicles, where engine noise is minimal, NVH plays a pivotal role in the overall vehicle performance.

To meet these expectations, every component that contributes to insulation, particularly in the HVAC insulation system, must:

- Maintain rubber form and sealing under temperature changes

- Avoid rubber seal degradation over time

- Prevent sound transmission and vibration transfer

This is where EPDM sponge rubber HVAC insulators play a crucial role.

Role of HVAC Insulator in NVH Management

The automotive HVAC insulator rubber wraps around HVAC pipes and ducts that carry cold or hot air into the cabin. These ducts run through the dash, center stack, or roof liners. Without proper insulation:

- Cold air can cause condensation and rattling

- Vibration from the blower or engine compartment can travel into the cabin

- Thermal expansion and contraction can lead to joint noise

- Poor sealing can lead to whistling, buzzing, or humming sounds

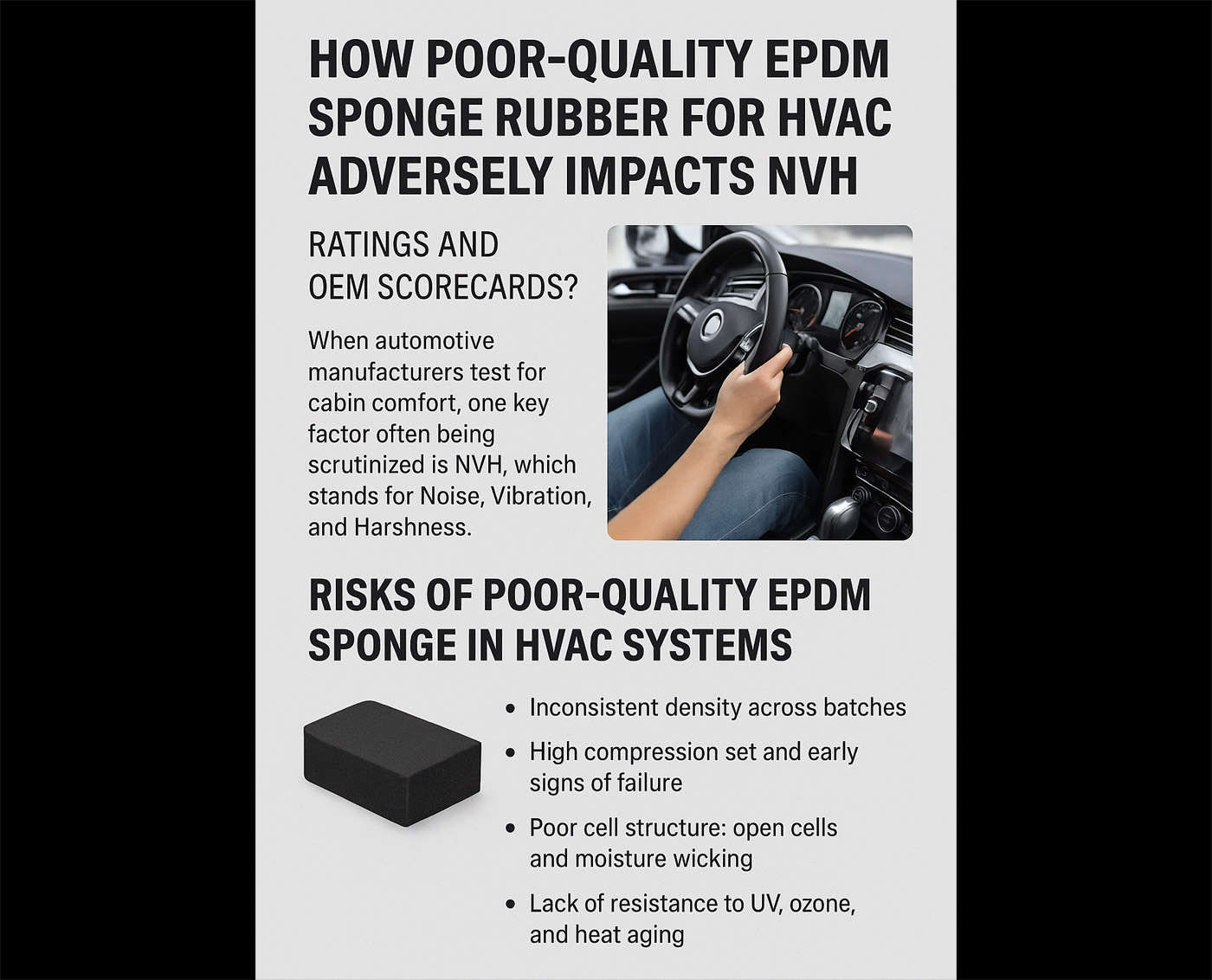

Risks of Poor-Quality EPDM Sponge in HVAC Systems

Choosing the wrong grade of EPDM sponge rubber for HVAC insulation may seem like a minor issue. However, it can invite a cascade of hidden problems that can derail your automotive sponge rubber quality, production efficiency, and relationships with Tier 1 or OEM customers. HVAC insulators help in noise damping and thermal control. Therefore, even minimum flaws in the composition or consistency of EPDM sponge rubber can have severe consequences on NVH (Noise, Vibration, Harshness) performance and reliability.

Below are the key risk areas suppliers must actively monitor:

1. Inconsistent Density Across Batches

Poor-quality EPDM sponge exhibits uneven foam density, which results in unpredictable performance in insulation and vibration damping.

- Effect on NVH: Inconsistent density leads to specific sections of the HVAC ducting vibrating, generating unusual noise that can be detected during NVH chamber tests.

- Quality Issues: Suppliers frequently face rejections during end-of-line (EOL) or audit testing due to fluctuations in insulation effectiveness.

- Operational Challenges: Difficulty in achieving consistent press-fit tolerance when wrapping ducts or inserting parts into assembly modules.

2. High Compression Set and Early Signs of Failure

Compression set indicates the ability of the rubber to retain its original shape after compression. A low-quality EPDM sponge exhibits a high compression set, indicating a loss of elasticity over time due to repeated heating and cooling cycles from the HVAC system.

- NVH Failure: As the material relaxes, it no longer exerts sufficient pressure to seal or isolate the vibration points. This results in joint movement, rattling, or buzzing sounds during operation.

- OEM Consequence: Parts may pass initial QA but fail within a few thousand kilometers of use, causing warranty claims and returns.

- Lifecycle Cost: The replacement of facade seals or insulation after installing includes extensive labor, tooling time, and potential customer dissatisfaction.

3. Poor Cell Structure: Open Cells and Moisture Wicking

EPDM sponge must ideally be tightly linked to prevent water absorption and to function effectively as a thermal and acoustic insulator. However, low-grade sponge rubbers may have discrepancies or open cells, either due to subpar compounding or incomplete vulcanization.

- Performance Issues: Open cells allow moisture ingress, causing insulation failure, microbial growth, and odor issues within the ducts.

- Mechanical Challenges: Wet insulation increases component weight, leading to compromised duct mounting. It also accelerates corrosion in surrounding components.

- Audit Failure: High moisture retention is flagged in HVAC condensation simulation tests used by OEMs to evaluate performance and durability.

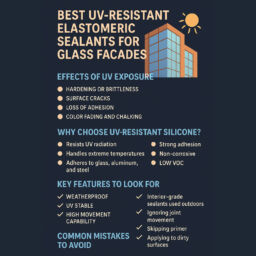

4. Lack of Resistance to UV, Ozone, and Heat Aging

Rubber insulators near engine compartments, firewalls, or under the dashboard experience prolonged exposure to UV, heat, and ozone. Subpar EPDM sponge rubbers lack the additive package to endure this stress.

- Physical Impact: The rubber insulator becomes chalky, brittle, or develops surface cracks within months.

- NVH Issues: These structural breakdowns allow air leakage and pipe vibration, generating whistling or fluttering noises at various fan speeds.

- Safety System: Cracked and crumbled rubber may block the airflow into the components or HVAC filter mechanisms, leading to blockages or system failure.

5. Variables from Outsourced Compounding

In the pursuit of cost savings, some suppliers procure pre-compounded EPDM sponge from third-party vendors without material traceability or laboratory test certifications.

- Quality Issues: Each batch may vary in foam ratio, filler content, and cross-linking, resulting in unpredictable NVH behavior.

- Sourcing Challenges: No visibility for batch failure till you invest in forensic-level testing.

- Reputation Damage: OEM audits may expose a lack of upstream control, flagging your company as a high-risk supplier.

6. Incompatibility with HVAC Assembly or Adhesives

Inferior EPDM sponge rubber may interact chemically with mounting adhesives, clips, or foam tapes used in the HVAC system. This can lead to:

- Loss of bond between the insulator and the duct

- Decline during thermal cycling

7. Failed Compliance with Industry Standards

EPDM sponge used in the automotive sector must comply with ASTM, ISO, and specific OEM standards for environmental and mechanical performance. Substandard materials often fail to meet:

- ASTM D1056 compression set

- ISO 7326 ozone resistance

- Flammability (FMVSS 302) requirements

- RoHS or REACH compliance

- Even if your part design is approved, your BOM (Bill of Materials) or raw material certification may be rejected, resulting in delays in production release.

Thus, poor-quality EPDM sponge may cut short-term costs, but it drastically increases long-term risks in automotive HVAC insulation systems. These rubber components are no longer “invisible” parts. OEMs now audit their NVH performance, compression set rubber NVH, thermal resistance, and traceability.

Tier 2 auto suppliers must treat the procurement and validation of sponge rubber with the same rigor as they do for structural components. After all, a slight vibration or noise today could be a lost platform tomorrow.

OEM Scorecards & Supplier Risk

Automotive OEMs use supplier scorecards to track:

- NVH compliance

- Parts Per Million (PPM) defects

- Delivery performance

- Validation and material compliance

- Tooling traceability

If your HVAC parts fail because of poor sponge rubber:

- You risk line rejection

- May need to retool and revalidate

- Could be blocked for future RFQs

- Lose cost advantage due to hidden quality failures

Best Practices: What Sourcing Heads and QA Teams Must Do

To avoid these pitfalls, here’s what Tier 2 automotive suppliers should implement:

Material Validation:

- Use sponge rubber with validated NVH test data

- Ensure compliance with ASTM D1056 (compression set)

- Ask for thermal cycling and ozone resistance test reports

- Demand PPAP, TDS, MSDS, and batch traceability

- Check the closed-cell EPDM insulation structure

Design Considerations for HVAC Insulators

If you’re involved in HVAC duct design or sourcing, here are your key takeaways:

| Spec Parameter | Ideal Requirement |

| Compression Set | <25% (ASTM D1056) |

| Shore Hardness | 25–35 Shore A |

| Cell Structure | Fully Closed |

| Temperature Range | -40°C to +120°C |

| UV/Ozone Resistance | ISO 7326 certified |

| Density Uniformity | <±10% across batch |

| Thermal Conductivity | Low, for insulation |

Shore A hardness is now discontinued by ASTM for sponge

Partnering with a trusted EPDM rubber manufacturer that offers –

- In-house compounding and testing labs

- IATF 16949 and ISO 9001:2015 certifications

- Prototyping support for duct fit and sound mapping

- Consistent delivery with minimal batch variation

What the Future Holds: NVH in Electric Vehicles

As vehicles become noise-free, the margin for NVH errors decreases. In EVs:

- No engine = higher sensitivity to HVAC noise

- Blower noise, duct buzzing, or joint squeaks are highly amplified

- Customers expect luxury-level silence even in economy EVs

That’s why automakers are increasingly asking Tier 2 suppliers to:

- Participate in early design validation

- Use materials with proven NVH performance

- Provide data-backed material traceability

Get the Best Rubber Profile and Enhance Your Market Reputation

You may think the HVAC insulator is a minor part, but it has significant consequences if it fails in NVH testing. From rejected lots to lower scorecard ratings, the use of low-grade sponge rubber can:

- Derail your Tier 1 or OEM partnerships

- Force revalidation or redesign

- Cost you bids on competitive platforms

With over 15 years of material science and extrusion experience, Saga Elastomer is your partner in high-performance HVAC insulation for NVH-sensitive applications.

How Saga Elastomer Supports NVH-Optimized HVAC Rubber Insulators

At Saga Elastomer, we specialize in producing EPDM sponge rubber explicitly designed for HVAC insulation in automotive systems.

What We Offer:

- Custom foam densities to match the required NVH damping

- Closed-cell EPDM that prevents moisture absorption

- Excellent anti-ozone and anti-aging properties

- Compression set consistently <20%

- Support for early-stage prototyping and validation

- Batch traceability and PPAP documentation for OEM audits

Our sponge rubber products are engineered to perform—both in the lab and on the road.

Want to validate your HVAC sponge rubber for better NVH performance?

Visit Saga Elastomer and book a material review call with our automotive rubber team today.