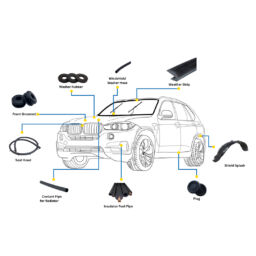

In high-performance building envelopes, especially façades, even the smallest components play a very crucial role and have the potential to make a significant difference. Façade rubber profiles play a pivotal role in preventing air and water ingress, providing insulation, and accommodating thermal movement. However, exposure to ultraviolet (UV) rays affects the rubber extrusions, which are a frequently overlooked factor.

In harsh outdoor environments, UV rays break down rubber polymers over time, leading to seal degradation, cracking, and reduced performance. This is why UV-resistant rubber profiles are more than just a mere feature when selecting rubber extrusion for facade projects.

This blog dives deeper into this topic, explaining the importance of UV-resistant rubber profiles in facade projects. Whether you are an architect, site manager, or façade engineer, this blog will provide you with an understanding of UV monitoring rubber profiles and guidance on selecting the right and durable material for your projects.

Why UV Resistance Matters in Façade Rubber Profiles?

Facade rubber profiles are constantly exposed to sunlight. In high-rise façades, curtain walls, skylights, and the perimeter seals experience:

- UV radiation

- Ozone exposure

- Rain and wind-driven moisture

- Temperature swings

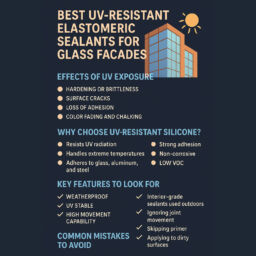

Over time, UV light can:

- Break down polymer chains in rubber

- Causes hardening or brittleness

- Reduce flexibility, leading to cracking

- Diminish sealing performance

- Lead to seal failure

This results in moisture ingress, air leakage, fogging, and even thermal bridging, which impact the rubber profile durability and jeopardize a building performance.

What Makes Rubber UV-Resistant?

UV resistance in rubber is achieved through a combination of materials science, compounding expertise, and process excellence.

Here are the five critical factors:

- Base Polymer Selection: The molecular structure of the rubber determines its inherent UV resistance. EPDM (Ethylene Propylene Diene Monomer) rubbers have a saturated backbone that resists the chain-scission caused by UV radiation. In contrast, natural rubber and some synthetic elastomers, such as styrene-butadiene, degrade faster due to their unsaturated double bonds. EPDM extrusion for buildings is widely used due to its long-term resistance to UV and ozone.

- Silicone polymer – Silicone rubber is great for façade projects because it resists damage from sunlight very well. Its special silicon-oxygen structure makes it stronger and more stable than regular rubber when exposed to UV rays. This means it keeps its stretchiness and strength for a long time, even when in constant sunlight. It also doesn’t become brittle or break down easily, so it lasts longer. Because of these qualities, silicone rubber is a reliable and smart choice for sealing building façades that need to stay durable and flexible over time.

- Carbon Black Loading: Carbon black acts like a sunblock for rubber, protecting it from the UV radiation. It absorbs UV rays and restricts them from entering the rubber matrix. This protects the rubber from damage, cracking, and discoloration.

- Stabilizers & Antioxidants: Additives such as hindered amine light stabilizers (HALS) and phenolic antioxidants are blended into the rubber during the compounding process. The additives help to neutralize the free radicals generated by UV exposure before they damage the polymer chains. This delays the appearance of oxidation on the surface and invisible cracks.

- Rubber Linking Density:

Rubber profiles, when processed with sulfur- or peroxide-cured compounds, often affect their cross-linking density and tightness. When the matrix is tightly connected, it increases the dimensional stability and prevents the rubber from softening under exposed sunlight. Saga optimizes these parameters based on application zones, including coastal regions, high-altitude areas, and other geographic conditions. - Quality Checks:

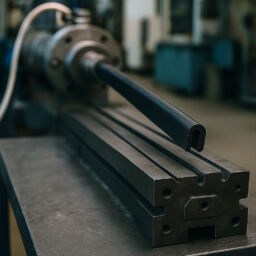

Even the best compound fails when the extrusion or curing process is inconsistent or incompatible with the quality checkpoints. Uneven filler distribution, temperature inconsistencies, or incomplete curing can create weak zones where UV damage accelerates. Saga uses in-line QC systems and statistical process controls to deliver uniformity across all batches.

Introducing: UV Monitoring Rubber Profiles

Innovative façade systems are starting to include UV monitoring rubber profiles, where the rubber extrusions are embedded with:

- Color-change indicators (that shift when the seal is no longer UV-effective)

- Embedded sensors that track seal ageing

These help facility managers proactively schedule maintenance and avoid failures.

Saga Elastomer suggests conducting R&D to integrate sensor-based compression set monitors and explore photochromic coatings for future innovative sealing systems.

Why UV Monitoring Should Be Part of Your Specification?

- Allows early intervention before total facade seal failure

- Reduces the lifecycle cost of building maintenance

- Supports predictive maintenance schedules

- Adds value to sustainability and building performance goals

8 Design Specs to Focus on for Rubber Extrusion UV Performance

When designing facade rubber profiles for durability in high-performance buildings, ensure that your rubber extrusion specifications exceed the dimensional tolerances. It must reflect the environmental stressors expected during the building’s lifespan, especially UV exposure. Choosing the right façade seal profile is not only a decision made by the procurement team; it is also a crucial consideration for the design team. It ensures a design insurance policy. Use these expert tips to ensure your next project avoids costly UV-related failures:

- Temperature Compatibility:

UV performance often degrades at extreme temperatures. Specific materials rated from -40°C to +120°C are critical for covering daily and seasonal thermal cycles, particularly in high-rise or glass-heavy facades, where microclimates can form behind panels. - EPDM or Silicone for Exposed Seals

Avoid using natural rubber, nitrile, or thermoplastics in areas with high UV exposure. EPDM’s resistance to degradation, cracking, and ozone makes it the gold standard for architectural use. Silicone offers even greater temperature stability, though at a higher cost. For visible seals, ask about UV-resistant colorants or silicone-coated EPDM rubber extrusions. - Carbon Black-Rich Compounds for Sun-Facing Surfaces

While aesthetics sometimes demands grey or colored seals, black rubber offers maximum UV protection due to its carbon content. Use pigmented rubber only in shaded or interior applications unless additional stabilizers are added. - Material Compatibility with Structural Silicone Glazing (SSG)

Incompatible sealants can speed up ageing. Verify that your rubber extrusion doesn’t chemically interact with glazing silicones or façade frame coatings. Request the compatibility testing and certificates of compliance for all rubber profiles. - Engineering-Led Rubber Supplier Early

Rubber profile design is not a mere cut-and-paste process. Engaging with potential suppliers early in the design stage facilitates the extrusion of hardness of the rubber profiles. It also helps to incorporate indicators, thereby enhancing both performance and maintenance. This also helps to reduce design corrections and avoid field failures. - Resistance to Salt Spray:

In coastal areas, UV damage is often escalated by salt-laden air. Select rubber profiles for coastal projects tested per ASTM B117 or ISO 9227 for corrosion and elastomer degradation under salt fog conditions. - Ozone Resistance:

UV and ozone often co-occur in urban air. Ensure the rubber passes the ASTM D1149 (Ozone Resistance Test) with no visible cracks. - Color Fastness:

If rubber seals are exposed (open-joint façades or sunshades), you may want profiles that resist discoloration. Some EPDM compounds are treated with UV-stable pigments and photo-resistant agents to avoid fading.

Saga Elastomer develops custom rubber formulations tailored to your project’s regional challenges.

Hidden Costs of Ignoring UV Performance

Ignoring the UV performance on time can slowly lead to bigger post-installation seal failures, resulting in several hazards –

- Replacing failed seals post-installation is labor-intensive and expensive

- Seal failure affects thermal insulation and raises energy bills

- Poor sealing can void façade warranties

- Customer dissatisfaction and litigation risks

A proactive spec compliance during the design stage saves time, cost, and reputation later.

Our team works closely with architects and façade consultants to ensure that the seal solution enhances both design and performance, today and for decades to come.

Final Thoughts

UV resistance in façade rubber profiles is more than a checkbox. It’s your shield against costly long-term failures. By investing in innovative, high-performance rubber solutions today, you save on repairs, energy, and rework tomorrow.

Saga Elastomer’s Preparation for Innovative & Durable Seals

With façade design evolving rapidly and buildings pushing new performance standards, rubber seals must evolve too. Saga is exploring:

- Low-VOC, RoHS-compliant compounds for green buildings

Saga Elastomer’s Advantage: Rubber Profile Durability You Can Count On

Saga Elastomer is a trusted name among the facade rubber extrusion manufacturers. Here’s why global clients rely on us:

- Customized compounds tailored for UV, ozone, and weather resistance

- In-house extrusion tooling and die design for precision fit

- Process control & traceability, each batch is documented

- IATF 16948 and ISO 9001:2015 certified production

- Accelerated weathering test capability (ISO 4892)