40 Shore A SBR is one of the most technically demanding yet essential materials for municipal water sealing systems. While most suppliers struggle to maintain shape and consistency at such low hardness, Saga Elastomer has developed advanced compounding and die-design capabilities that ensure reliable, field-tested performance for every batch.

Why Most Suppliers Struggle With 40 Shore A SBR

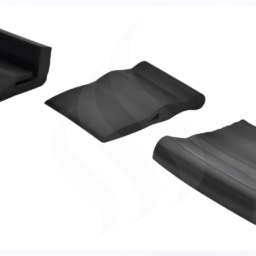

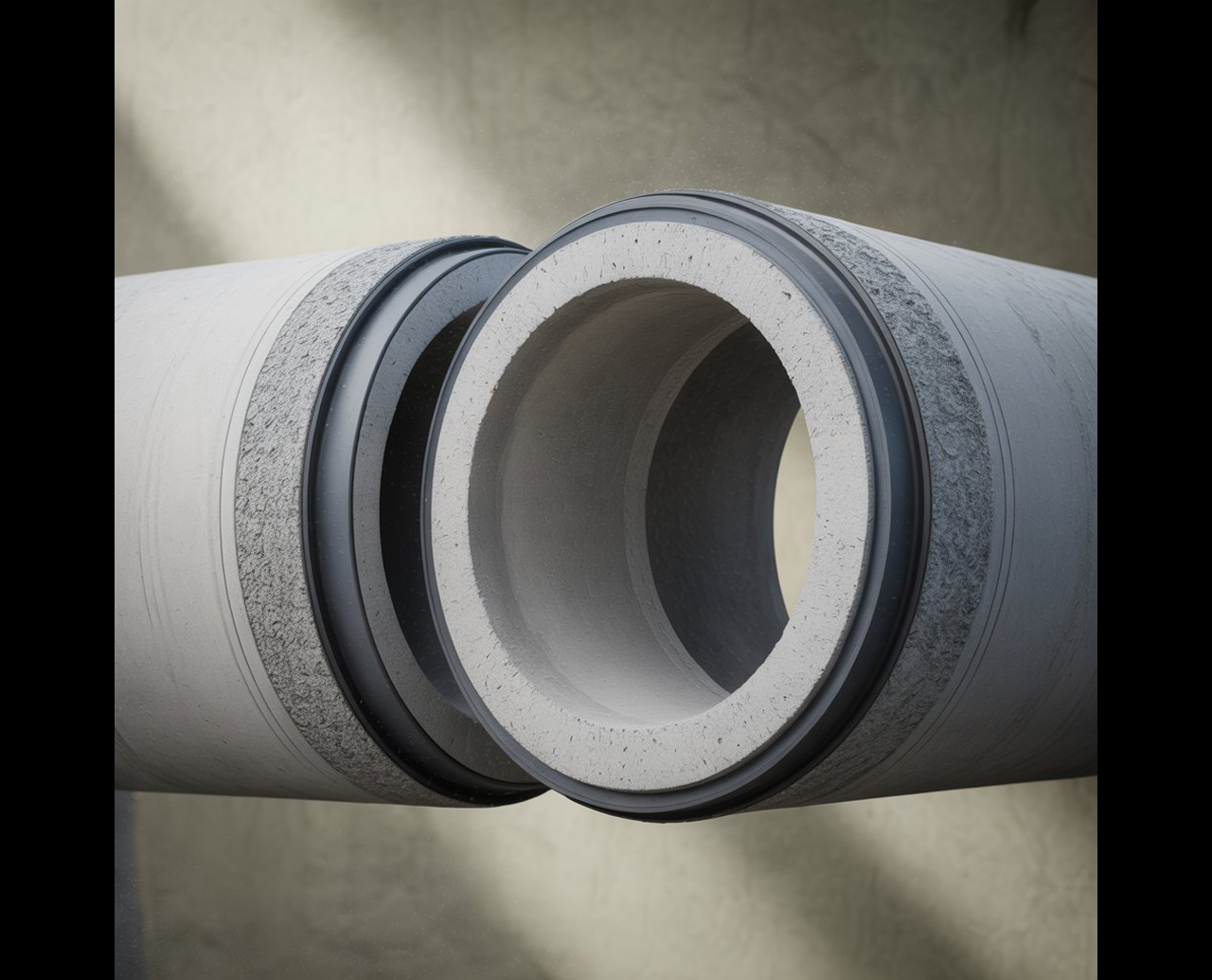

When we talk about sealing materials in municipal water pipelines, the focus is usually on reliability and long-term performance. One of the lesser-known yet high-demand materials in this category is 40 Shore A SBR (Styrene-Butadiene Rubber). This specific grade offers just the right softness to seal tightly while adapting to surface variations in pipes and couplings. But manufacturing this rubber profile isn’t easy.

In fact, most suppliers avoid it altogether.

This article explains why, and more importantly, how SAGA ELASTOMER has developed an edge in producing reliable, consistent, and field-tested 40 Shore A SBR profiles for critical water infrastructure applications.

Why 40 Shore A SBR Is Used in Pipe Sealing

Municipal water systems deal with everything from old, worn-out pipelines to new HDPE or PVC setups. Rubber gaskets and O-rings used in these lines need to be soft enough to compress into rough surfaces without cracking, yet firm enough to maintain their shape under pressure. This is where 40 Shore A SBR excels.

Key Advantages:

- Softness for sealing: Easily conforms to uneven pipe surfaces.

- Pressure-appropriate: Ideal for low to moderate pressure lines.

- Cost-effective: Compared to silicone or EPDM, SBR is more affordable.

- Vibration absorption: Its elasticity dampens minor pipe movement.

However, these advantages come at a cost during manufacturing.

The Real Manufacturing Challenges

While many rubber manufacturers are comfortable with Shore A 60 or 70 SBR profiles, going softer brings in a host of technical problems.

1. Shape Retention Issues

40 Shore A SBR is soft enough that, after extrusion, the profile can flatten under its own weight before it fully cures. This is especially true for round cords above 15 mm in diameter.

Why it matters:

- Misshapen gaskets lead to uneven sealing.

- Poor roundness affects tolerance matching with pipe grooves.

What makes it happen:

- Incorrect cooling timing.

- Under-optimized die design.

- Poor green strength (the material’s ability to hold shape before curing).

2. High Compression Set

Compression set is a measure of how much a rubber seal fails to recover its shape after being compressed. SBR at 40 Shore A, if not compounded correctly, tends to lose elasticity quickly.

Result?

- Seal flattens permanently.

- Leakage risk increases over time.

3. Dimensional Variations Between Batches

When working with soft rubber, even a 1°C temperature shift during extrusion or a 2% variation in plasticizer can create inconsistent results.

Common problems include:

- Variation in cord diameter.

- Surface roughness or gloss issues.

- Inconsistent hardness readings across the length.

4. Tooling and Die Wear

Soft SBR requires extremely precise tooling to prevent swelling or tapering during extrusion. However, that same softness can accelerate tool wear, leading to frequent recalibration and maintenance.

Why Most Suppliers Avoid It

To get 40 Shore A right, manufacturers need:

- Customized compound formulation

- Specialized low-durometer die design

- Real-time quality control

- Tight batch-to-batch process consistency

Most standard rubber profile manufacturers don’t have this level of process control, or the margins to support it. The result? They stick to safer hardness levels, often offering Shore A 60+ as a substitute.

But in doing so, they miss out on performance benefits that only true low-durometer profiles can offer.

How SAGA ELASTOMER Solves the 40 Shore A Puzzle

SAGA ELASTOMER has been producing soft rubber profiles for over three decades. But what sets us apart is our deliberate investment in solving low-hardness manufacturing challenges.

1. Custom Formulated SBR Compounds

Our internal compounding team fine-tunes:

- Plasticizer types and levels

- Reinforcing fillers

- Antioxidant and anti-ozonant systems

The result?

- Soft profiles that hold their shape.

- Extended aging resistance in field conditions.

2. In-House Tooling Design

We build our dies to suit low-durometer materials. That includes:

- Adjusted flow channel geometry.

- Reinforced die face materials.

- Precision exit gap tolerances.

This lets us control swelling, maintain profile roundness, and improve run-to-run stability.

3. Statistical Process Control (SPC)

We track:

- Diameter across multiple points.

- Line speed vs. cure temperature.

- Extrusion stability per shift.

Every batch is monitored in real time using SPC tools. Variations get flagged and corrected on the spot.

4. Real-World Testing and Field Feedback

We don’t stop at the lab. Profiles undergo:

- Real-world pipe fitment checks.

- Compression recovery tests post-aging.

- Installation trials with select EPC contractors.

This feedback loop helps us tune compounds and processes even further.

Practical Applications in Municipal Water Supply

Where 40 Shore A SBR Really Shines:

| Application Point | Benefit of Low Hardness SBR |

| Pipe-to-pipe couplings | Better sealing on rough joints |

| Flange gaskets | Adapts to warped surfaces |

| Repair sleeves | Easy to compress and install |

| Expansion joints | Absorbs minor shifts without leak |

These uses are common in both new pipeline installations and maintenance projects.

FAQ

Is 40 Shore A SBR suitable for pipe sealing?

Yes. It’s actually ideal for low-pressure systems that need seals to compress easily and adjust to uneven surfaces. But the key is using a well-compounded and well-extruded product.

What is 40 Shore A rubber?

This refers to the material’s hardness, measured on the Shore A scale. 40 is considered soft and is commonly used where flexibility and surface conformity are needed.

Why do some seals fail in municipal systems?

Often because of high compression set, poor curing, or the wrong hardness profile. Choosing the right material and manufacturer can prevent this.

How does SAGA ELASTOMER ensure consistency in soft rubber profiles?

Through a mix of custom formulations, in-line quality checks, and field validation. Every profile batch is tracked from compounding to packaging.

Final Thoughts

Producing 40 Shore A SBR profiles that seal reliably is a technically demanding task. But the payoff is clear: tighter seals, longer life, and fewer field failures. While most suppliers struggle with shape distortion, compression issues, and inconsistent hardness, SAGA ELASTOMER has built a proven system to get it right.

If you’re sourcing soft rubber seals for municipal water infrastructure, it’s worth choosing a partner who doesn’t just make profiles—but makes them work.