Custom Rubber Products Manufacturer

Saga Elastomer is an ISO 9001:2015 accredited company having a working culture that is highly systematic and process oriented. A highly sophisticated plant with latest machinery, equipment, testing facilities, an experienced & well-trained team, perfectly documented processes and traceable product tools & batches form the very backbone of our systems.

Our customers vouch for our passion for precision, inclination for innovation and moreover, with the humility that we do our business. Our customers have highest regards for our values, ethics, knowledge and capabilities and hence have been with us for longer period of time.

When you chose Saga, you know all your demands will be fulfilled with utmost care, superior quality, precision, meeting your timelines and most importantly, maintaining transparency & communication.

Our Primary services and infrastructure

Saga thrives to serve not as a mere service provider, but as a caring partner on our clients’ journey to success.

Our ability to ideate, design and precisely manufacture the challenging products for various industries has been a path breaker for our clients.

We manufacture and supply high quality custom extruded rubber products to various industries like Architectural industry, Civil Engineering industry, Thermal, Electrical, Solar, Hydro power industries, Rail & Road transport, Shipping &Marine, Mining, Oil, Gas, Water distribution and automotive industry. We also work very closely with contractors for road & bridges construction, glass facades, curtain walls & structural glazing, door and aluminium as well as uPVC windows manufacturers.

Saga infrastructure:

Manufacturing

Our up-to-date in-house manufacturing capabilities are based on not only the 2000 Square Metres of own land but our vision to meet our customers’ needs from prototype to large run production parts, saving time, energy and money for them. Major strength of Saga lies in our own compounding operations which have been developed with continuous efforts and precision. Our latest machinery comprises of multiple mixing mills, kneaders, continuous vulcanising lines, conventional extruders, autoclaves, boilers, etc. All of the products undergo stringent quality checks during and post manufacturing through our latest testing instruments.

We source high grade raw material directly from international companies to ensure impeccable quality and consistency. These virgin materials and other ingredients are processed under computer control into specified formulations to meet stringent quality and product precision requirements. We also ensure to upgrade our machinery to process & manufacture to latest technology.

Our team responsible for packing and shipping ensures safety of products and maintains continuous communication flow with our customers.

Our customer support team is always eager & proactive to solve queries & issues being faced by our customers.

The strength of Saga is in its belief in continuous learning and Team Saga is always open for suggestions which we treat as value additions to our business.

We are passionate about

process and precision.

We deliver products with your stringent

quality norms.

We follow strict timelines,

every time.

Integrated partner in your

progress and success.

We collaborate & accommodate your

last minute changes.

Bespoke product development and

embrace changing technology.

Enhancing experience by clear and

timely communication.

Building long lasting relationships

with our clients.

updates

Discover how good quality, customized industrial rubber drum seals play a crucial role in enhancing efficiency and safety at work. Improper drum sealing can result in product loss, contamination, safety hazards, and regulatory non-compliance, leading to financial setbacks and reputational damage. By understanding the true cost of inadequate sealing and exploring effective solutions provided by industrial rubber drum seals, organizations can mitigate risks, ensure product integrity, and maintain a safe working environment. Partnering with a reliable manufacturer like Saga Drum Seals can provide tailored sealing solutions, superior performance, and peace of mind.

EPDM sealing rings are crucial components in pipelines that transport liquids and gases. However, installing them can be challenging, with common issues such as longevity, compression set, tight spaces, and compatibility. In this blog, we explore the solutions on how to avoid four common mistakes made by pipe contractors. By choosing the right materials & suppliers, considering the gasket dimensions and compression set, and opting for specially designed gaskets, contractors can achieve a secure and reliable seal that prevents leaks and damage to the pipeline.

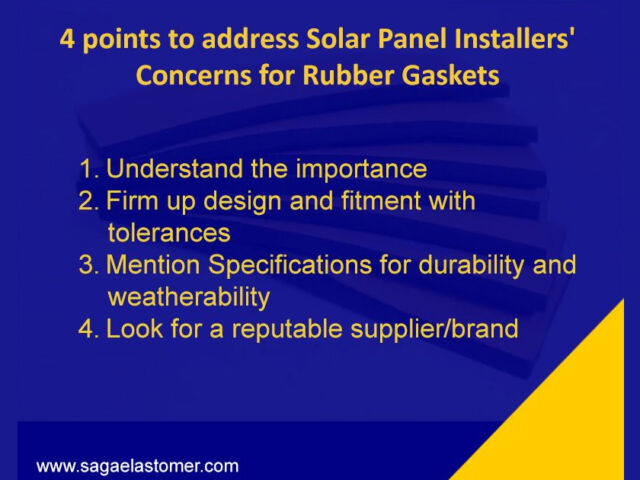

Learn how high-quality rubber gaskets can address concerns faced by solar panel manufacturers and suppliers. Discover how SagaSure’s EPDM rubber gaskets provide a cost-effective solution for producing efficient and long-lasting solar panels. Find out how Saga’s rubber profile and rubber pads can protect your panels from damage during installation and harsh weather conditions. Read on to find out how you can ensure the longevity and optimal performance of your solar panel system with Saga’s high-quality materials.

News

We are delighted to share the December’23 edition of Industry Outlook Magazine featuring your trusted partner in driving innovations in bespoke rubber manufacturing, Saga Elastomer Pvt Ltd!

We are thrilled to share that Saga had the pleasure of hosting esteemed international customers at our plant. It was an incredible opportunity for us to showcase our commitment to global partnerships and deliver exceptional experiences to our valued guests.

Our Chairman Mr. M J Laddha is now 80years young. He is the epitome and live example of the statement “Age is just a Number”. He has been actively involved not just in strategic planning but also day to day operations. He is a guiding force behind the positive changes Team Saga has seen in last couple of years