Saga Expansion joint profiles

Definition

An expansion joint profile is a device or an assembly that allows two parts to hold together during temperature (heat) induced expansion and contraction. Pipelines, building faces, concrete slabs, railway tracks, etc expand and contract due to heat induced due to high temperature and cold due to lower temperatures. If there are no expansion joints, these would crack under the pressure induced.

They are specially designed to

- Holds parts together

- Withstand various temperatures.

- Absorb temperature induced expansion and contraction of the materials used in construction.

- Allows movement due to traffic, ground movement, natural calamities like earthquakes, etc

- Absorbs vibrations.

Usage

Expansion joints are used in-

- Sections of buildings

- Railway tracks

- Ships

- Construction of sidewalks & bridges

- Piping systems

Normally, modular expansion joints are used in construction of buildings, bridges, etc. Modular expansion joints are generally made of combination of metal and rubber.

Team Saga has been manufacturing expansion joint rubber profiles for more than a decade. One of the extruders we had was a 75 mm cold feed rubber extruder. According to conventional wisdom & machine manufacturer, it was good enough for an extrudate of max 4 kgs per meter, with max dimensions of 100*100 mm.

Challenge

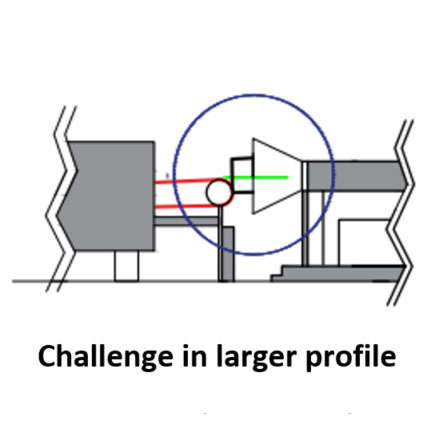

Then, one fine morning, we get an enquiry for expansion joint block profile with outer dimensions 100* 150, weighing about 7 kg per meter.

It was challenging and as it’s true nature, Team Saga decided to give it a try. The Team had a hunch that with some tweaks, this extruder may give this output though at a lower speed.

Solution

Firstly, the communication (transparency with customer): Team Saga informed the client that this task is too big for our extruder but we are accepting it as a challenge & it may or may not work (The risk was of Rs 50,000/ USD 800 then).

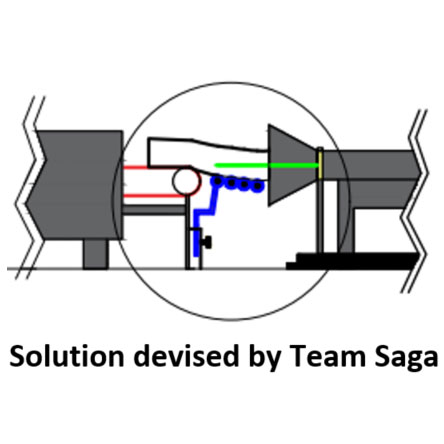

Team Saga designed a head to hold an extrusion tool of 240 mm OD & also the tool.

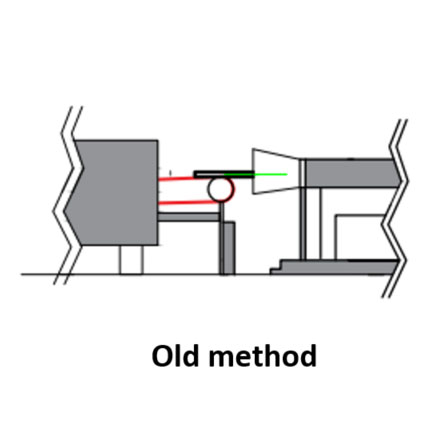

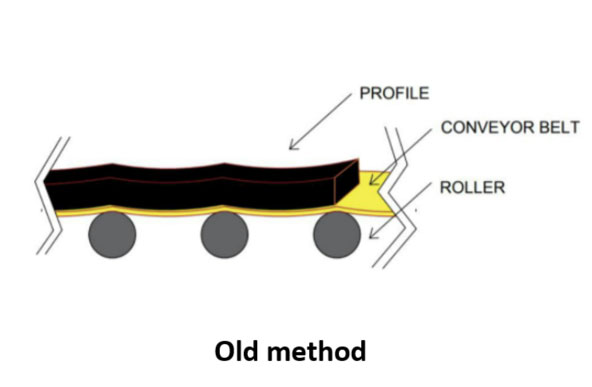

The major challenge was then to adjust the output & belt of CV line to be at the same level (Illustrated below).

Thirdly, it was designing an EPDM compound (the recipe) which had excellent flow & green strength, so that the profile does not collapse in the microwave line.

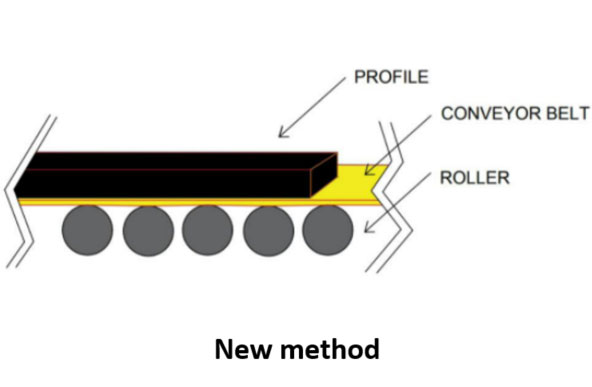

Lastly, it was to give additional support to the belt, so that it can take the complete load (Illustrated below).

Finally, with these innovative adaptations & modifications, Team Saga was confident of getting the extrusion in the precise way as per the drawing and the piece extruded beautifully well in the first attempt itself.

When we shared this news with the machine manufacturer, he could believe only after seeing the video.

The key takeaway that Team Saga derived thru this was to never have limitations of thoughts in the mind and everything is possible if we put serious efforts and follow our heart with perseverance.

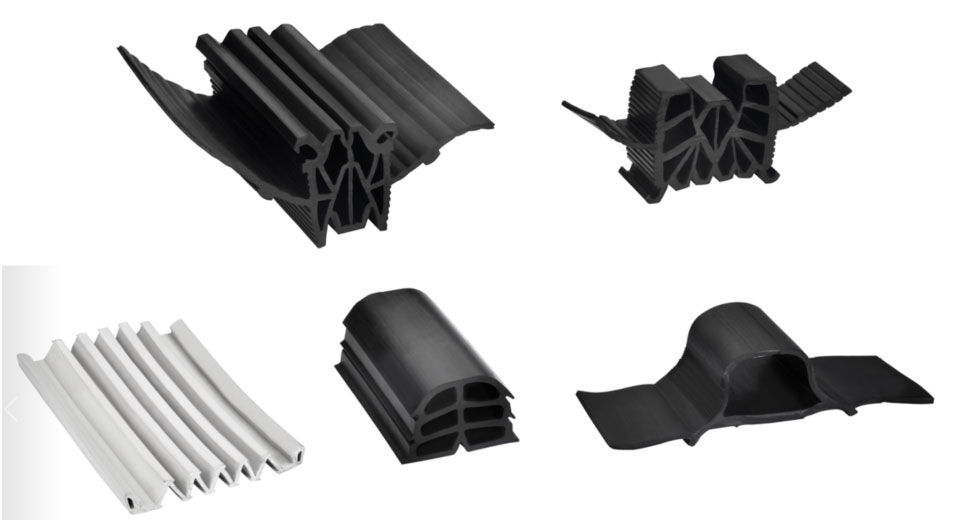

Team Saga manufactures and exports expansion joint profiles of multiple dimensions in various synthetic rubber materials.

Combination of logical mind and a brave heart works magic!

Please do like, comment and share this to spread knowledge.

Various designs of Saga Expansion Joint profiles