Saga Elastomer has been in rubber extrusion business since almost three decades and has been instrumental in offering solutions to customer’s challenges. However, Team Saga is conscious not to become complacent and keeps learning, innovating and follows process.

This blog is about how Team Saga faced a challenge in recent times and overcame.

The Challenge

We recently had an order for fender wherein the specifications said EPDM fender should have minimum 40 % polymer content.

Our experience with EPDM for the last nearly 3 decades made gave us confidence that this shall be an easy task, but rubber has its own way of humbling people and we found this when we started trial runs of the same.

Typically, a combination of polymers is used to create rubber fenders. E.g., natural rubber (NR) and synthetic rubber (SR) like EPDM, with fillers like carbon black (CB), calcium carbonate (CC), and other additives to provide reinforcement and processability. While there is a consensus in the industry regarding the majority of components used in fender production, ideas about the quality of the ingredients and their ratio diverge widely from manufacturer to manufacturer.

Typically, fenders can be made in Natural rubber / SBR or EPDM depending on customer specs and/or usage conditions with fillers like carbon black (CB), calcium carbonate (CC), and other additives to provide reinforcement and processability. While there is a consensus in the industry regarding the majority of components used in fender production, ideas about the quality of the ingredients and their ratio diverge widely from manufacturer to manufacturer.

These standards provide guidance as to the physical characteristics of rubber fenders, including others as tensile strength, compression set, and elongation at break. However, there is no international standard that outlines the chemical composition of the rubber compound used to make rubber fenders.

In other words, there are industry standards that outline a specific objective for the production of marine fenders in terms of their functionality, durability, and physical characteristics, but there is no advice on how to get there. This is due to the fact that no two fender manufacturers or projects are alike.

Every project has different needs that call for specially customized rubber compositions. Additionally, not all types of polymers used to make fenders are equally accessible throughout the world, thus producers must modify their rubber compounds accordingly. All of this gives fender manufacturers plenty of leeway for market differentiation and chances to offer their own best practise methods for creating high performance products.

We first discussed with our customer about our plan and how we want to execute the same. The customer was highly supportive & appreciative of our proactive approach & transparency.

The fender was about 15 kg per meter profile and a tool was made to start the extrusion.

But here came the first road block. The size variations in extrusion left us totally confused and dumbstruck. For a dimension of 150 mm the size variation was from 140 mm to 160 mm, very much above the expected and accepted range.

We discussed with our customer and apprised him of this road block and & our solution.

Solution

We changed the EPDM grade to one with medium mooney so that the load on the extruder would reduce and variations may come down. This did have some effect but still not to our satisfaction. Team Saga then went back to drawing board, looked at the problem from a different perspective and again discussed with our customer.

We then did a lot of tweaks to stabilize the rubber compound. We also made a conveyor so that the uncured rubber profile can roll on and not increase the back pressure on the extruder as we had to make fender in a larger length.

Despite all of these efforts we could not achieve the required stability in dimensions. We then discussed with our customer saying we can do this only with 30 % polymer content and maybe they can do the testing of the same and then give us a go ahead if it passes all requirements.

It was only upon approval of our customer, who was appreciative of our genuine efforts & transparency, the sample with lower polymer content was submitted. It passed all tests and we got the order with the amendment so that we could immediately execute the order.

Conclusion

Any good, successful relationship is built on the principles of transparency, openness, dedication and honesty. When you use them in your interactions with clients, the results will start to become evident quickly. Transparency leads to more honest and relevant feedback, which can be utilized to improve products or services accordingly. As it was evident in the above case.

It goes without saying that honesty and transparency builds trust. You can create brand loyalty by being upfront and honest with your customers and demonstrating that you value their feedback.

However, you still have the choice of explaining what happened to their input and give honest reasons. Will it be put into practice, is it still under consideration, or was it shot down?

Team Saga would highly appreciate readers views and suggestions for improvement. Do comment & share if you liked our experience and learning.

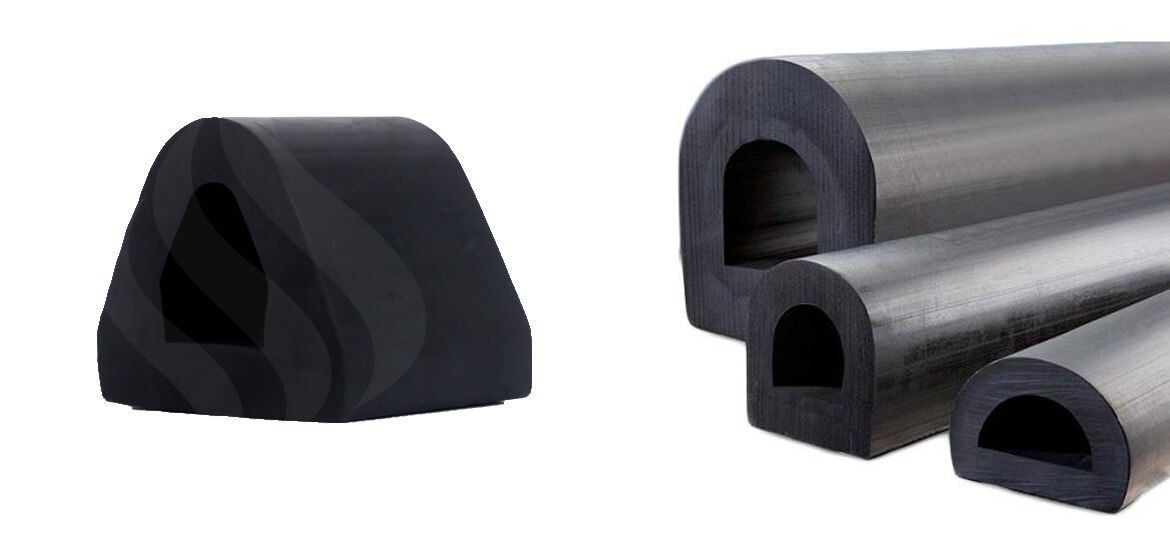

Saga EPDM Fenders

What are fenders?

The capacity of rubber to withstand water, saltwater, wind, sunshine, temperature extremes, and other environmental conditions makes it a popular material in the shipping and marine industries. In boats, ships, yachts, cruises, and other vessels, every component, including rubber, is essential. Therefore, choosing the proper compounds is essential for comfortable sailing for both marine buyers and ship builders.

A fender is a type of bumper intended to dissipate the kinetic energy generated when a boat or other vessel docks against a jetty, quay wall, or another vessel.

Rubber fenders protect ships and berthing structures from damage and are used on various types of boats, including cargo ships, cruise ships, ferries, and private yachts.

Features and benefits of Saga EPDM fenders

- High resistance to impact and tearing

- Resistance to adverse climates and high temperatures

- Resistance to salt water and resistance to corrosion

- Prevents damage to vessels and birthing structures

- High durability

- Cost effective

- Easy installation

- Wide range Customization options available

Relevant Links: