A lot of people are in the mistaken belief that extrusion of chords is very simple and can easily be done by any extrusion products manufacturer. Though this may be true to an extent for standard (60 to 70 Shore A) hardness chords, the task becomes much more complicated when you have to produce the same with low hardness range (e.g. 40 Shore A). We came across such a challenge few months ago which gave us an opportunity to look at the process differently to ensure desired result for our esteemed customer.

The key challenges in making chords or any profile of such low hardness are as follows

- Shape retention during manufacturing process

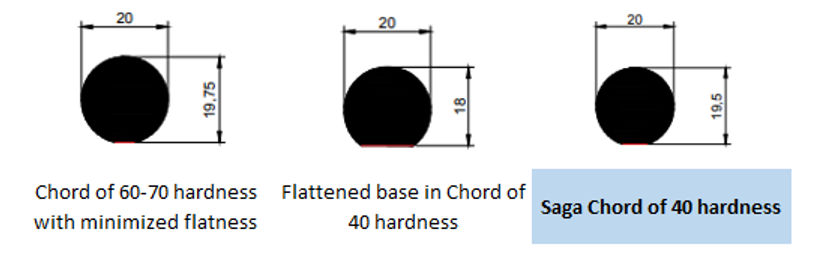

The chord tends to flatten due to its own weight, that is the profile cannot sustain its own weight even during extrusion. This leads to shape change to the extent that it cannot be used functionally. Also, as the back pressure is too less managing the size within tolerances is another challenge.

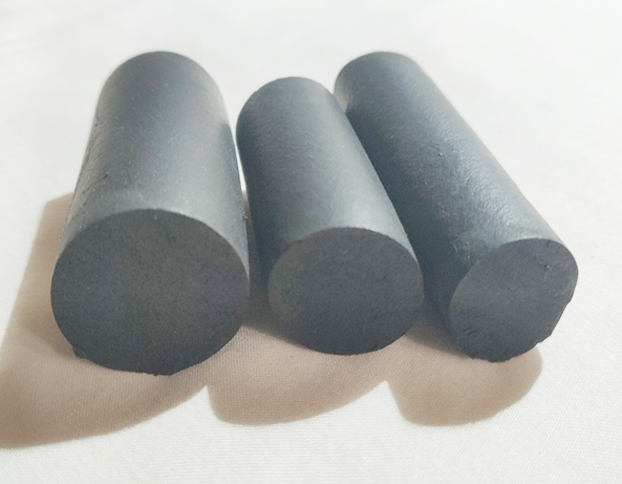

Please see the illustration below

When manufacturing chords of 22 mm to 32 mm the weight per meter increases a lot and hence the concentricity of the chords is lost. The flat base becomes larger and larger.

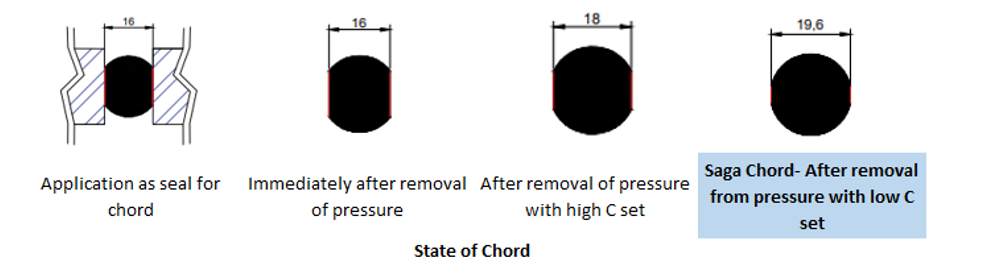

- Shape retention during application.

Big challenge lies in ensuring low compression set (C Set) of the chord to ensure shape retention during application of the chord for sealing. This is a key property that impacts application of sealing as ideally the seal should keep exerting reverse pressure (indefinitely in time) on the substrate so that perfect sealing is obtained. This can be achieved only if the rubber seal /chord has very low compression set.

Please see the illustration below

The solution is combination of following aspects-

Type of polymer: The type of polymer used plays an important role in processability of these low hardness chords. EPDM is the simplest to process even at this low hardness. However, the problem arises when it is used to extrude chords as pipe seals, compression set property becomes very critical. Also, exposure to external conditions being minimal, natural rubber or SBR are very good materials for these conditions. However, processing at such low hardness with SBR or natural rubber is a challenging process.

Compound: Special compound has to be developed to overcome these issues of shape retention by using additives. These additives in turn should also help in increasing the green strength of the compound.

Manufacturing process: Batch ageing and uniform extrusion temperatures help a lot in managing the size within tolerances and adjusting the curing in such a way that onset of curing happens almost within 5 meters of the chord coming on to the conveyor.

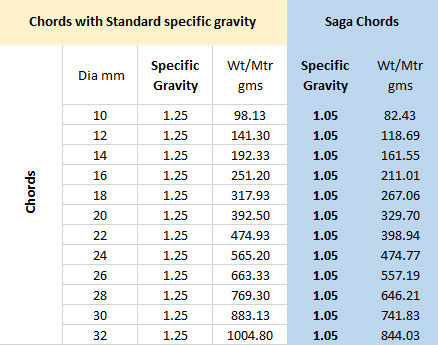

Specific Gravity: At Saga, we have developed special (very pure) compound that has specific gravity of only 1.05 which helps in lowering the compression set. The chords developed by us have low compression set values and good roundness in shape which helps achieve the function of sealing perfectly and consistently over a long period of time. Please see table below

Alternatively, these low hardness chords can also be produced on LCM curing lines but since we don’t have this facility as of now, we had to develop a compound with above tweaks.

As a result of these efforts and ensuring quality keeping prices competitive, we were awarded by repeat orders of FCLs by our overseas client.

Team Saga has developed chords in SBR polymer too.

If you like the blog, if you can add an improvement, I would request you to comment & share to reach maximum people who can get benefited from this.