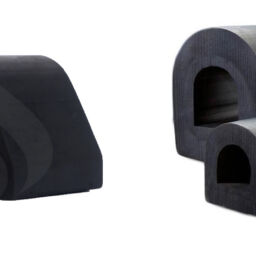

Industrial rubber gaskets serve many industries with simple but critical functions. Majority of gaskets are quite low on cost; however, they are not always interchangeable between applications.

The performance and longevity of the rubber gasket can be affected by the material choice, which will eventually lower the maintenance, replacement and downtime costs.

While silicone is a popular high-performance material used in many applications, there are times when an Ethylene Propylene Diene Monomer (EPDM) gasket is a better option.

EPDM and Silicone Rubber: What are their properties and uses?

Silicone Rubber

Both silicone and EPDM are useful depending upon the application. Our customers are aware about already It will be easier to choose the ideal material for the project if you are aware of the qualities and capacities of each material. The extraordinary endurance of silicone rubber to extremely high and low temperatures is well recognized. Due to the material’s superior compression set property, it has extra advantages for gaskets. Additionally, silicone offers exceptional resistance to corrosive substances, ozone, water, fire, and ageing.

Additionally, silicone rubber is thought to be sterile and suited for use in the food and beverage industry since it resists the growth of fungi. Since silicone rubber gaskets last for a long period, there is less need for replacement and less downtime for the equipment. Silicone rubber is used widely in a variety of sectors and is suited for a wide range of applications due to its adaptability.

EPDM

The EPDM material is abrasion resistant and has a tensile strength that is greater than silicone and the majority of other polymers. It is possible to synthesize EPDM to maintain its flexibility even at very high temperatures. Additionally, it has good heat and oxidation resistance and can survive the impacts of ozone and UV rays. EPDM swells when exposed to oils and petroleum compounds, yet it is highly resistant to steam and almost all acids and alkalis.

Many outdoor rubber gasket applications are made possible by EPDM’s ability to operate at low temperatures as well as its resilience to moisture, sunshine, and extreme weather. Its strong electrical resistance qualifies it for various electrical applications, and its good compression set allows it to recover well in situations where a joint may periodically open up.

Choosing the appropriate rubber gasket material for your application is crucial, even though gaskets are a very inexpensive component in comparison of other parts. However, failure of rubber gaskets can damage entire finished part/assembled part. These damages frequently result from improper material selection for the environment. Many aspects need to be taken into account when picking between Silicone rubber and EPDM as a gasket material.

Conclusion

Until they are completely satisfied with your offerings, your customers won’t be particularly delighted to spend money on your product or service. It becomes challenging for a customer to make a decision since multiple businesses are offering comparable solutions and the difficulty in establishing confidence. A happy customer will be more inclined to use your brand and services again in the future since they trust you. Team Saga has always maintained this trust among our customers and provided them with the best of our offerings.

Links:-