Why Premium custom rubber profiles take more time and efforts

Many customers ask this question to us, as to why does a custom rubber profile takes so much time to produce?

The answer is simple- Rubber profiles have to be precise in their applications and hence you need to devote time for perfection & precision. Careful and advance planning is required for several steps to arrive at a final product.

Gathering of information-application, drawings, specifications, quantities, timelines, etc.

Ask questions & clarify doubts.

Feasibility study.

Offer suggestions if any.

Take confirmation from customer.

Preparation/Selection of compound based on requirements.

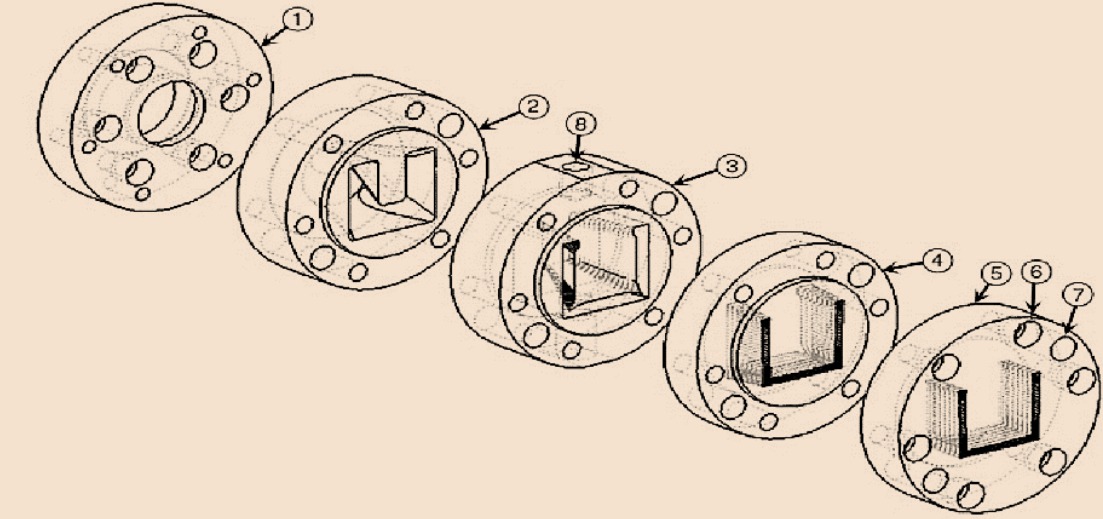

Planning for die – Once the compound is finalised, taking into consideration the die swell & flow characteristics.

Trials & sampling

Pilot lot- Highly recommended to go for pilot lots even after sample approval. There are sometimes issues detected only after actual installation and application/usage.

It’s highly advisable to go thru each step meticulously and maintain records. Adherence to these steps will ensure standardization, proper quality and delivery consistently.

Extruded Rubber and Die

Extrusion is a manufacturing method that produces items with a set cross-sectional profile, like rubber lengths. Rubber profiles are extruded), and a metal instrument known as a die is necessary for each extrusion. Material is forced through a die with the desired shape and size to create this cross-section. The die design depends upon the material of choice, properties & quantity needed. Therefore, die plays a pivotal part in the extrusion process.

Extrusion Dies

Materials used

There are several and different kinds of materials that is used for rubber extrusion. The class of polymers, known as elastomers, comes in a wide variety of forms. Commodity materials typically cost less than speciality compounds, although the cost of commodity rubber changes according to the cost of raw materials and the law of supply and demand.

Time taken to extrude Custom rubber profile depends on

The length of time an extruder requires to develop depends on how complicated a custom rubber profile is. There are also timescales for engineering and design. You should also factor in the time needed to extrude the specific bespoke rubber profile. This typically takes 8 to 14 weeks. The work can occasionally be completed more rapidly, but not if the profile is complicated.

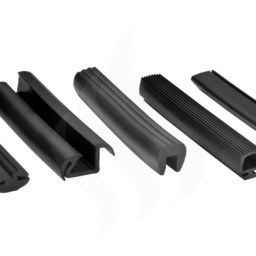

The products that are made through rubber extrusion process

Rubber Seals & Gaskets

For a wide range of sealing requirements, our rubber gaskets and seals are perfect. A particular kind of seal created to occupy the space between two connected parts or regions is known as an extruded gasket. EPDM rubber seals, flare trim, extruded rubber tubing, rubber edge trim, locking gaskets, and o-ring cords are a few of our common sealing extrusions.

At Saga, we create our rubber gaskets and seals while taking all considerations into account. High-level performance is provided by our sealing components in even the most demanding applications.

Custom Extruded Rubber Profile

Customizability is one of the main benefits of the rubber extrusion method. Each form of rubber extrusion has a particular set of uses and advantages and can be found in a wide range of shapes, sizes, and configurations. Although rubber extrusions are most frequently used for sealing, they can also be utilised to manage vibration, absorb impact, reduce noise, and even add decoration to your home’s windows.

Team Saga can generate a variety of extruded rubber profiles thanks to our knowledge with the rubber extrusion technique. For almost any project, we can develop the ideal rubber profiles using high-precision machinery.

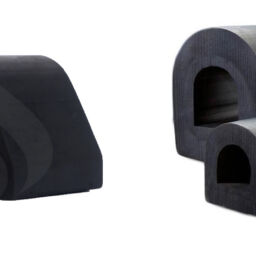

Rubber Window glazing

A type of seal that stops air, water, and other liquids or gases from leaking through windows is extruded rubber window glazing. These seals may also be referred to as glazing gaskets, glazing strips, or weather stripping. Window glazing is most frequently used to lower energy usage in residential and commercial buildings. These seals are ideal for keeping the heat or air conditioning inside, which will save your gas and electricity costs.

Car doors, windscreens, airline window seals, sunroofs, boat hatches, and more are some more uses for window glazing. But not all window glazing must adhere to the same design standards.

Industries to which rubber extruded products are supplied

Rubber extrusions are used extensively in a variety of industries, including architecture, automotive, civil engineering, aerospace, marine, infrastructure, medical, food processing, and others, for sealing and impact absorption. Extrusions are available as rollers, sheets, and rods for usage in warehouses and industries to absorb the loud noises and strong vibrations produced by large machinery.

Continue reading our blogs to find out more about different products we manufacture, challenges faced & how Team Saga overcame the same.

Saga Elastomer Pvt Ltd (SEPL) is a manufacturer & exporter of extruded rubber products. We support more than 400 customers and add value to their growth aspirations. Every customer receives a finest product for their application thanks to our experience, expertise, willingness to innovate, precision, sophisticated machinery, and moreover the passionate Team Saga.

Links:-